Introduction

A beam subjected to bending experiences a bending moment and a shearing force at each section of the beam which vary both in intensity from one section to another section and along the beam. Stress induced in the beam are produced by the bending moment.

When a beam is loaded on top side, the fibers the section of the load application experiences compression force while fibers on the underside of the beam experience tensile stress.

Objective

The main of objective of this experiment is to determine the curvature of a timber sample.

APPARATUS

Bending apparatus, timber sample, dial gauge and Vernier gauge.

PROCEDURE

- The height (h) and the width (w) of the timber sample was measured using a Vernier gauge.

- Clamps from the background were removed and the beam was set up in place.

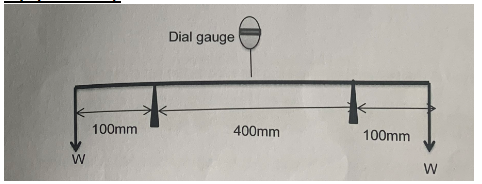

Equipment setup

- Knife-edge hangers were slide on each end of the beam.

- The digital indicator was then slide into the center position between the two knife-edge supports and locked in place using a rear thumbnut.

- The frame was slightly taped and the digital indicator set to zero using the origin button.

- The masses were added to the knife hangers in increments of 100g while tapping the frame slightly every time.

- The readings of the digital test were recorded for every mass increment.

DATA

Measured timber sample.

Height (h)=6mm

Width (w)= 18mm

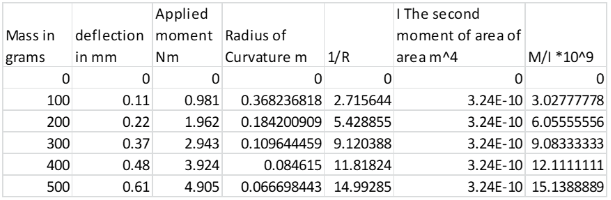

Tables of collected data

ANLYSIS

Calculating applied moment (

Example

Calculating the second moment of area

Calculation of radius of curvature R

Example

Calculating the value of 1/R

Example

The other data was transferred into excel spreadsheet for complete solutions

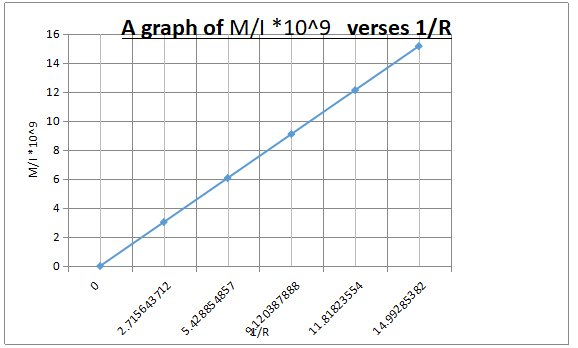

Graphical drawing

From the beam formula

Rewriting the equation in terms of equation of a straight line

(mathcentre)

Where

s

Calculating the gradient of the graph

DISCUSSION

The value of the young modulus obtain is , this caluclated value of Young’s Modulus lie between the acceptable limits. The value of the young modulus is relatively low since it belongs to wood which is less rigid as compared to metals. The accuarrcy of the experiment can be improved by using different types of woods with know value of Young’s modulus and the experimentally calculated value of individual wood be compared with the theoritical value of that wood also it can be improved by reducing the amount of load applied at every interval and allowing the timber to rest fully before measuring the deflection and finally the cord length of the timber to be used should be determined and accurate.

The value of the young modulus calculated is the standard value of the young modulus are of softwood is between 0.9 and 1.87 which indicates that the results obtained lies within the range of softwood. Based on the accepted value of E this type of wood can be classified as Redwood. (AmesWeb)

The value of the young modulus of timber indicates how rigid the timber will be when subjected under different kind of forces. This value indicates the strength of the timber when used for structural purposes. It is very essential in determining the amount of loads that a particular structure will be able to sustain (CodeCogs).

The strength of wood is determined by cellulose microfibrils being stretched. The number of cell spaces in the wood that is filled by both air and water determines the strength of wood. Timber having less cells spaces and water has higher strength hence higher young modulus that the wood with more cell spaces and more water. (Construction)

References

AmesWeb. YOUNG’S MODULUS (MODULUS OF ELASTICITY) OF WOOD. june 2013. https://amesweb.info/Materials/Youngs-Modulus-of-Wood.aspx.

CodeCogs. Youngs Modulus. 11 May 2013. <https://www.codecogs.com/library/engineering/structures/youngs-modulus.php>.

Construction, American Institute of Timber. “Timber construction manual.” Wiley, 2012.

mathcentre. Equations of straight. February 2019. http://www.mathcentre.ac.uk/resources/uploaded/mc-ty-strtlines-2009-1.pdf.

| Mass in grams | deflection in mm | Applied moment Nm | Radius of Curvature m | 1/R | I The second moment of area of area m^4 | M/I *10^9 |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 100 | 0.11 | 0.981 | 0.368236818 | 2.715643712 | 3.24E-10 | 3.027777778 |

| 200 | 0.22 | 1.962 | 0.184200909 | 5.428854857 | 3.24E-10 | 6.055555556 |

| 300 | 0.37 | 2.943 | 0.109644459 | 9.120387888 | 3.24E-10 | 9.083333333 |

| 400 | 0.48 | 3.924 | 0.084615 | 11.81823554 | 3.24E-10 | 12.11111111 |

| 500 | 0.61 | 4.905 | 0.066698443 | 14.99285382 | 3.24E-10 | 15.13888889 |