Ans 1) Process Flow diagram :

Gold recovery from the sulfide concentrate typically involves further refining, usually by roasting or oxidation of the wet air. Such pyrometallurgical or hydrometallurgical treatments themselves are typically accompanied by techniques of cyanidation and carbon adsorption for the final gold recovery. Hydrometallurgy involves the application of aqueous chemistry to recover metals from ores, concentrates and recycled or residual materials. This method is used to remove less electro-positive or less reactive metals such as gold or silver. Gold recovery chemicals such as lime, sodium carbonate, sodium hydroxide, and sulfuric acid are used for slurry pH adjustment; sodium sulfide is used for activation; water glass and phosphate are used for dispersal; flocculation and starch are used for flocculation.

The process flow diagram for the hydrometallurgical processing of the gold ore using the Carbon in Pulp ( CIP ) process has been shown here. The ROM ore is used as the feed stream. The gold bars are used as the product. The comminution, beneficiation and hydrometallurgical aspect the gold purification have been separated.

Figure 1

The Figure 1 shows the various steps. The run of mine ore is given to the crushing and/or milling stage. The next step is thickening which includes lime flocculant. The cyanide and air/oxygen are added for leaching process. Carbon adsorption is then done and residual disposal is done. Carbon adsorption gives loaded carbon for acid washing with hydrochloric acid ( Sole, 2018 ).

Then, carbon elution is done using cyanide hydroxide which generates eluant for electrowinning or zinc precipitation which generates gold. The carbon elution gives carbon regeneration using steam. Then, carbon conditioning is done using fresh carbon to give the regenerated carbon to the carbon adsorption stage ( Petrov, 2018 ).

The Carbon – in – pulp ( CIP ) comprises of the sequential leaching. After tis, the gold is adsorbed from the ore. In the CIP step, the pulp is made to flow from various agitated tanks. Here, the sodium cyanide and the oxygen are added for dissolving the gold in the solution. The gold yield is reduced by the attraction of the gold which was there for carbon in the activated form. In this method, leaching is done in the initial couple of tanks. Leaching is made to continue and the carbon adsorption takes place.

Ans 2) A stream table is produces for the process. The streams considered are which enter or exit the 4 PFDs. Data used in stream table is : Pso particles size, Water flowrate, solids flowrate and flowrate.

The design criteria is given by :

| Item | Value | Units |

| Total solids feature | 100 | Tonnes / hour |

| Solids feed Pso | 600 | Mm |

| Solids work index | 15 | kWh / tonne |

| Gold content | 3.5 | Grams /tonne |

| Silica content | 999996.5 | Grams / tonne |

| Weight (g) | Flow – Outlet 1 ( ml / CS ) | Flow – Outlet 2 ( ml / CS ) |

| 2001 | 1000 / 117 | 1000 / 134 |

| 18975 | 1000 / 116 | 1000 / 111 |

| 18864 | 1000 / 103 | 1000 / 145 |

| 189863 | 1000 / 95 | 1000 / 146 |

| Outlet flow ( ml / CS ) | Water content in concentrate recovered ( Weight % ) | Water content in cyanide recovered ( Weight % ) |

| 1000 / 45 | 9.6 | 9 |

| 1000 / 40 | 9.6 | 9 |

| 1000 / 48 | 9.6 | 9 |

| 1000 / 48 | 9.6 | 9 |

3. The half reaction for gold reduction is at the top of the electrochemical series, above the reaction for the disassociation of water.

The precipitation of gold from aqueous cyanide solutions is not thermodynamically spontaneous because gold is insoluble in water. Cyanide can help to stabilize gold in the solution which also needs oxygen for dissolving the gold. When gold mixes with dilute cyanide ( of sodium, potassium or calcium ) and air is bubbled then gold gets oxidised and forms aurocyanide complex ion ( Birloaga, 2014 ).

Gold shows a stable state with oxidation state of +3 in the electrolyte having the unit activity for the dissolved gold and the thiocyanate ions. If the concentration of the oxygen dissolved falls, then the equilibrium potential gets shifted to the negative side. Then, the +1 oxidation state becomes stable. If an oxidising agent is present, then gold is not stable thermodynamically. The electrowinning is required to precipitate gold out of cyanide solutions because the trace amounts of gold need to be recovered from the solutions.

Ans 4) Purpose of elution stage on a gold plant :

As we know that elution is the process of extracting any material from another material by the use of a solvent. The washing of loaded ions will exchange resin to remove the captured. It is the process of recovery of gold in the carbon in pulp process. The process requires the heating of caustic cyanide for many hours. Also sodium sulphite when used can affect the rate of reaction with full accuracy by four times ( Baba, 2014 ). The process is used to de absorb gold from activated carbon. Ethanol can also be used for the process. The solvent molecules called the eluate should travel down by the column. This phase is called as the stationary phase. This process displace by binding to the absorbent. After this phase the mobile column passes out of the column which is then collected form analysis. Since the process has a lot of safety concerns the process does not get accepted easily. In the process of gold extraction, the first column is called carbon column. Here the carbon absorbs gold form the solution that is provided ( Birloaga, 2013 ). The second step is the elution. In this process the carbon is released from the gold and both are separated.

References :

Baba, A. A., Ibrahim, L., Adekola, F. A., Bale, R. B., Ghosh, M. K., Sheik, A. R., … & Folorunsho, I. O. (2014). Hydrometallurgical processing of manganese ores: a review. Journal of minerals and materials characterization and engineering, 2(03), 230.

Birloaga, I., De Michelis, I., Ferella, F., Buzatu, M., & Vegliò, F. (2013). Study on the influence of various factors in the hydrometallurgical processing of waste printed circuit boards for copper and gold recovery. Waste management, 33(4), 935-941.

Birloaga, I., Coman, V., Kopacek, B., & Vegliò, F. (2014). An advanced study on the hydrometallurgical processing of waste computer printed circuit boards to extract their valuable content of metals. Waste Management, 34(12), 2581-2586.

Petrov, G. V., Fokina, S. B., Boduen, A. Y., Zotova, I. E., & Fidarov, B. F. (2018). Arsenic behavior in the autoclave-hydrometallurgical processing of refractory sulfide gold-platinum-bearing products. International Journal of Engineering and Technology (UAE), 7(2), 35-39.

Sole, K. C., Mooiman, M. B., & Hardwick, E. (2018). Ion exchange in hydrometallurgical processing: an overview and selected applications. Separation & Purification Reviews, 47(2), 159-178.

Reflection on Miss Evers Boys

Miss Ever’s boys’ film it’s a fractionalized interpretation of the Tuskegee study of untreated syphilis in the Negro Male between 1932 and 1972. It was a 40-year project in which the US government was tracking the course of the disease of the many black men living in Tuskegee, the essence of the study was to withhold treatment; the penicillin and determine whether the black Americans responded similarly to the effects of the disease just as like the whites. Therefore, the purpose of the study was to know if the penicillin was able to prevent and cure the syphilis infection and whether the disease had the similar effect to the blacks (Alsan, and Wanamaker, 2018 p,407) However, the participants who were infected by the disease did not get the medical treatment The United State government sent a medical investigation to the poor African black men in Alabama in Macon country. The research participants consisted of 600 black men of whom 400 were infected with the contagious disease and 200 were not infected.

The government used them in conducting medical research and by the end of 1972, only 74 men were alive,28 of them died of syphilis, 100 dyeings with related diseases and 40 infected their wives with the diseases while more than 18 children of the men were born with congenital syphilis (White, 2019 p.371). The population of Tuskegee was selected as it contained most of the black Africans who were not affected by the diseases and it was suitable for the study. The Americans needed to test whether the Penicillin had the same effect of curing and preventing syphilis to the blacks and hence Tuskegee was suitable. Eunice Ever and Dr. Brodus were chosen to facilitate the program as they could be able to curb syphilis spread among the African American in rural Alabama, Ever gratified to be able to serve the community and it was believed she was the only person that made the participants believe that they were receiving medical care which helped them to cure the disease. Ever was able to hold every information about the research although filled with the dilemma of whether to disclose the information to the participants, do her duty as a nurse or just assume everything. One of the strategies Ever used to convince the participants was that she went around the town announcing that the government was providing free medical care for bad blood. Ever was able to assuage their fear of the painful tabs which she called them back shots and making them believe it was not painful at all. Ever was very social to the patients and interacted with the participants very well that such that she was affectionate and had a bittersweet relationship with a syphilitic individual who announces his love for her (Barrett et.al 2019).

From the three strategies used by Ever, she violated the ethical nursing ethics of Truth-Telling and Patient Consent by lying to them that they would receive free medical treatment while they did not receive the treatment. On the same Ever violated the nursing Ethics on fidelity by having an extensive relationship with Calen which is not professional within the nursing practice. However, it was very kind of Ever who fully participated in providing care for the participants and demonstrated the act beneficence by having an interest in improving the lives of the people in her region through medical care of syphilis. The US government used their power to promise free treatments to the infected blacks and promised to give them food and since the men had no food and lived in a poor economy, they were lured to the experiment (Hermann, 2000).

The participants were illiterate who came from poor economic backgrounds giving reasons why the government took advantage of them. Mis Ever was driven by the act of compassion and altitude of providing good care of the participants which is an act of beneficence. She felt that her role was to console the infected men of whom most of them were her friends. She was very social to the participants such that she even made romance with Caleb, one of the participants, who later joined the army.

I feel very proud of Mrs. Ever who had such great compassion for helping the participants and gratified to serve her community after the invitation form the federal government to participate in the medical research. Although she learned the truth of the experiment, she was confused seeing that there was no medical care administered to the patients, making her have a great dilemma on whether to quit the research. In case I would have been invited in the research by the American government I would have helped syphilis infected individuals get the medical care by intervening with the American government, making them understand the medical needs of the community and the economic pressure the people face. This could greatly help the communities reduce the death rates and get the treatment of the infectious disease as well as improving the economic pressures of the community.

This case relates to a case where more than seven psychiatric studies were closed down in New York University after it was discovered there were ethical violations and falsifying records. This led to some researcher’s dismissal and closure of the research centers. The violation included tax oversight and having failed to keep accurate records. It involved an individual who was diagnosed with posttraumatic stress due to drug abuse and the researchers were investigating whether the untested drug could improve her conditions. The patient is reported to be sexually harassed by the researcher and administered a wrong drug which led to her deterioration and later death (NYU medical school stops studies after ethical violations, 2020)

.

Both cases NYU and violates the nursing ethics of justice. The patients are entitled to have justice and fairness. The research participants in the Tuskegee Study required treatment justice as they had been promised free medical treatment on syphilis. Relatively the patient was diagnosed. with posttraumatic stress required fair treatment with the right drug. However, the two cases differ with the unfairness, where the Tuskegee study was on racism, only black was meant to suffer from unfair treatment while the test was never done to the whites though the whites did it. The NYU research was not racist and it could have been a medical error or negligence.

Some of the research ethics available today that can prevent Tuskegee Study incidences are the principle of the informed concert, where the researchers have to understand why they are performing the research, as well the expected goals or outcome. The principle of anatomy and confidentiality protects the researchers in that only researchers who are willing to participate in the research are involved (Giunta, & Sharp 2020). Then the researchers are bound to have confidentiality and maintain the research information confidential. The Principle of deceptive practices applies to the Tuskegee Study

References

Alsan, M., and Wanamaker, M., 2018. Tuskegee and the health of black men. The quarterly journal of economics, 133(1), pp. 407-455.

Barrett, L.A., 2019. Tuskegee Syphilis Study of 1932–1973 and the Rise of Bioethics as Shown Through Government Documents and Actions. DttP: Documents to the People, 47(4), pp.61-16.\

Giunta, H., & Sharp, R. R. (2020). Can the Principles of Research Ethics Help Us Distribute Clinical Resources More Fairly?

Hermann, D. H. (2000). Lessons Taught by Miss Evers’ Boys: The Inadequacy of Benevolence and the Need for Legal Protection of Human Subjects in Medical Research. JL & Health, 15, 147.

White, R. M. (2019). Driving Miss Evers’ Boys to the Historical Tuskegee Study of Untreated Syphilis. Journal of the National Medical Association, 111(4), 371-382.

Evidence based policy is a term mostly used in the public policy to explain how policy decision are based on objective evidence. With the increased political populism and contestation, availability of reliable information is crucial to come up with well informed policies that are based on evidence than emotions and feelings. The legitimacy of the current political systems are based on their ability to make and deliver proper results as a policy and law maker that focuses on facts. These results must have a basis of reliable information son that these political decision can be understood, assessed, sustained and be future focused. In the preparation and scrutinisation of policy making processes, arrangements are day after day being evaluated and assessed based on facts and statistics. These arrangements are on the policy proposals, legislations and implementation of these statistics and factual information. Complex steering mode is a form of evidence based monitoring which leads to alteration in patterns of governance, globalization and supranationalization. On the basis of complex steering mode, evidence based policing focuses on ways to restructure the association and relationship existing between political heads of various institutional origin and their political classes. It also focuses on policy mechanisms that distinguishes politics with policy approaches of different political systems (Cairney and Oliver, 2017).

Evidence based policing is important in the health care setting as well as in a country at large. Lancaster (2014) claims that evidence based policing has much of its impact on the developed nations and less established in the developing nations. An excellent utilization of evidence based policing could save lives. Eradicate poverty and improve the development performance in the developing nations. An example of this is an East African country that implemented the evidenced based policing in the health sector whereby health services were informed by household disease surveys. This led to reduction of infant mortality with a 40 percent margin. In different nations, HIV and AIDS crisis is becoming worse due to the governments ignoring the evidence of the cause of the infection and ways of preventing its spread. Oliver et al. (2014) claim that evidence based policing provided the best evidence attained from research for implementing and developing the policy hence individuals are in a position to make wise and informed decisions on projects, policies and programmes. It also makes scientific evidence and what is unknown to be understood. Unlike opinion based policing, evidence based policing must have policies that are anchored on evidence so as to shape agendas, define issues, identify options, make choices of action, deliver these choices and also be able to track the effects and results of the choices of action.

According to Saltelli and Giampietro (2017), the existing crisis on the governance of science affects the integrity of science, its reproducibility and scientific peer review, hence the need to look in to evidence based policing. The recent policy based policies apply the mechanism of quantification on the basis of analysing risks and cost benefits. They aim at optimizing one of the policies among different issues being considered. The analysis of this single policy is affected by distracting from alternative readings. These alternative frames lead to uncomfortable knowledge which should be excluded from the policy discourse. Leuz (2018) claims that the future of evidence based policy making should be based on disclosure and transparency mandates as this would make the process more fruitful and natural. In the past trust, accountability and transparency in evidence based policing have been misused reducing links with sciences. Professionalization agenda in policing is crucial as it supports the evolution process and how changes lead to overcoming forthcoming challenges. The police have in different nations have undergone learning to as to understand and appreciate the significance of agendas (Edwards, Gillies and Horsley, 2016).

The SARA model is a model in decision making that involves research and analysis, focusing solutions to a given problem and also evaluating how effective the solutions are. It was developed by John Eck and William Spelman in 1987. This model entails scanning, analysis, response and assessment. The scanning is the identification, selection and prioritization of issues that should be addressed using data from the community and citizen input, police and other data sources. Analysis involves thoroughly analyzing the causes of issues. These problems could include the continuous cause of crime and call for police services. Response is determining, evaluation and implementation of a call to a given problem. Ideas and actions towards response have to be evidence based or specific and focused to the given issues applying the existing sound mechanisms of preventing crime. Assessment is the most ignored aspect of the SATA model. This aspect calls for assessment and evaluation of the effect of a given response and being ready to apply a different approach if the response was not effective (Burton and McGregor, 2018).

The hot spot policing is a theory that focuses on the regions where crime is highly concentrated by directing correction activities and resources to those regions. It is also used in regions where violence and crime are dense but clustered in small regions. The resources and activities directed to these regions in an attempt to prevent, reduce the levels of crime or totally eradicate it (Braga et al. 2019). This policy does not involve the use of given tactics and interventions but targeting resources to a given high crime area. According to Kochel and Nouri (2018) this policy has been important in eradicating crime. The hot spot policing has a well-defined strategy that accounts for any publication bias and also applies relevant and right statistical techniques in analysis of effect size.

Problem oriented policing (POP) is a technique that involves diagnosis and solving problems that lead to increased crime in areas experiencing high criminal levels. The policing technique faces challenges as it has to carry out a diagnosis and then resolve the problems causing increase in crimes in a large locality. However, there are different ways of carrying out this technique. POP was coined by Herman Goldstein with the intention of replacing the existing policing standard models with more proactive approaches that can target and identify issues that lead to crime and disorder in the community. Problem oriented policing gets information on crimes and environmental issues causing risks in the society hence leading to a high level of crime reduction. It also improves and promotes the relationship within a community as it involves partnering with the local community. Problem oriented policing is sometimes used in resolving serious crimes especially when it involves collection of tips from the community then making follow ups. The POP mechanism can take different forms which vary depending on the issues at hand being resolved. The most common is the application of scanning, analysis, response and assessment to resolve a specific problem. POP can also target crime hot spots, focus on non-geographic concentrations of crime and other factors (National Institute of Justice, 2020). The base line of problem oriented policing is coming up with an issue which is narrowly defined then applying a wide range of responses to reduce the severity or combat the problem.

The lectures of supply chain management have pointed out importance of structure between head contractors and subcontractors and its performance (Munns, A. K. 1995, Kadefors, A. 2004, Segerstedt, A., Olofsson, T., Hartmann, A., & Caerteling, J. 2010). Still construction industry has poor trust culture (Green, S. D., Fernie, S., & Weller, S. 2005) that leads to unsuccessful of collaborative relationships (Dainty, A. R., Briscoe, G. H., & Millett, S. J. 2001). To promote the efforts of client and head contractors of construction supply chain management in interface of client and head contractors partnering agreements (Bresnen, M., & Marshall, N. (2000). This leads to backdrop of construction industry reforms in UK which creates unenviable sectors which is more relational and trust-based.

According to (Kumaraswamy, M. M., Anvuur, A. M., & Smyth, H. J. 2010) claimed that in recent collaborative framework agreements there is a failure of integrate subcontractors (SC), suppliers and consultants leads to major shorting of collaborative efforts. Most probably this research has discussed issues about subcontractors and suppliers in their collaborative agreements which includes belief, expense and seek to enhance their profitability. So subcontractors are seeking their own business requirements (Dainty, A. R., Briscoe, G. H., & Millett, S. J. 2001). With all these reasons how supply chain management system manages in construction sector and the company performances (Love, P. E., Irani, Z., Cheng, E., & Li, H. 2002). According to (Walker, A. (2015) all firms which are included in construction sector need to make visible for subcontractors and head contractors to contribute the other areas of construction. These improvements in supply chain management between subcontractors and head contractors could increase the future improvements in performance of construction companies. This requires certain research attention for the management of subcontractors.

Smyth, H. E. D. L. E. Y. 2011) indicated that some contractors continue to integrate collaborative activities as core competencies and complex skills in supply chains and networks to maximise value. It was during a time of economic downturn where the primary focus was on cost and company survival as opposed to the emphasis on collaborative activities that was common during the preceding era of economic growth. However, these joint initiatives by head contractors organisations have lost empirical focus in research into construction management. (King, A. P., & Pitt, M. C. 2009) Contractor-driven approaches argued about the customer-centered approach of Construction Supply Chain Management (SCM) literature. Given the several decades of adversarial working relationships and the consequent culture of mistrust (Ankrah, N. A., Proverbs, D., & Debrah, Y. (2009) that have hindered supply-chain integration, especially among SCs (Dainty, A.R.J., Briscoe, G.H. and Millett, S.J. (2001), trust is likely to remain fundamental to such collaborative efforts undertaken by contractors.

A contractor-centered emphasis on SCM practises adopted by UK head contractors and the possible implications of these practises for the creation of inter-organizational trust particularly during periods of austerity are likely to lead to long-term performance improvements. This study thus aims to bridge the gap in awareness by efforts of (King, A. P., & Pitt, M. C. 2009) on SCM practises from an HC point of view and then discuss the consequences of these practices form the functioning of inter-organizational structure practices in projects.

2 RESEARCH QUESTIONS

Based on the background of the research, the following research questions have been raised:

- How head contractors in UK managed subcontractors by adopting supply chain management practices.

- How inter organisation structure formed between head contractors and subcontractors in the projects by adopting supply chain management practices.

- How the impact of various supply chain management practices on project performance has been measured.

- What is the understanding between head contractors and subcontractors related to SCM relationships.

3 RESEARCH SCOPE

The scope of this research is implementation of supply chain management practices on construction and inner organisation structure and its performance in UK.

4 RESEARCH AIM AND OBJECTIVES

The main aim of this research is to explore inner organisational structure development between head contractors and subcontractors and its performance. Objectives of the research are listed below:

- To develop a clear definition of supply chain management for construction organisation and its performance as well as literature of supply chain management.

- To develop a best practice how head contractors are managed subcontractors of an organisation in UK.

- To develop best inner organisation structure between contractors and sun contractors.

- To investigate a case study how companies applies supply chain management practices to measure the organisation performance.

- To evaluate case study frameworks using selected construction practitioners involved in SCM related activities.

- To draw conclusions and recommendations for the use of SCM practices.

5 METHODOLOGY TO BE ADOPTED AND PROJECT SCHEDULE

This project is mainly divided in 10 chapters with subtopics in each chapter. The main study of this project is based on internet sources and journals which are available by library access. This is useful carry out chapter 2,3 and 4. The research methodology is mainly carried in two sources are 1) qualitative and 2) quantitative (Newman, I., Benz, C. R., & Ridenour, C. S. 1998). The best practices are chosen while conducting the project. The list of chapters and their subtopics are listed below table:

| Task Name | Duration | Start | Finish |

| CHAPTER 1 Research Introduction | 6 days | Thu 27/02/20 | Thu 5/03/20 |

| Research background | 1 day | Thu 27/02/20 | Thu 27/02/20 |

| Research questions | 1 day | Fri 28/02/20 | Fri 28/02/20 |

| Research aims and objectives | 1 day | Mon 2/03/20 | Mon 2/03/20 |

| Scope | 1 day | Tue 3/03/20 | Tue 3/03/20 |

| Structure of project | 1 day | Wed 4/03/20 | Wed 4/03/20 |

| summary | 1 day | Thu 5/03/20 | Thu 5/03/20 |

| CHAPTER 2 SCM concept | 6 days | Fri 6/03/20 | Fri 13/03/20 |

| Introduction of SCM | 1 day | Fri 6/03/20 | Fri 6/03/20 |

| SCM concept | 1 day | Mon 9/03/20 | Mon 9/03/20 |

| Emergence of SCM in construction | 2 days | Tue 10/03/20 | Wed 11/03/20 |

| SCM implementation in construction | 2 days | Thu 12/03/20 | Fri 13/03/20 |

| CHAPTER 3 Inner organisation structure concept | 7 days | Sat 14/03/20 | Mon 23/03/20 |

| Introduction | 1 day | Mon 16/03/20 | Mon 16/03/20 |

| Inner organisationb structure concept | 2 days | Tue 17/03/20 | Wed 18/03/20 |

| factors that influence inner organisation structure in construction | 3 days | Thu 19/03/20 | Mon 23/03/20 |

| CHAPTER 4 research design and methodology | 6 days | Tue 24/03/20 | Tue 31/03/20 |

| Introduction | 1 day | Tue 24/03/20 | Tue 24/03/20 |

| Research methodology and methods | 1 day | Wed 25/03/20 | Wed 25/03/20 |

| Research process | 4 days | Thu 26/03/20 | Tue 31/03/20 |

| Research design phase | 1 day | Thu 26/03/20 | Thu 26/03/20 |

| Literature review | 1 day | Thu 26/03/20 | Thu 26/03/20 |

| case study design | 1 day | Thu 26/03/20 | Thu 26/03/20 |

| Data collection | 1 day | Fri 27/03/20 | Fri 27/03/20 |

| Case studies data | 1 day | Fri 27/03/20 | Fri 27/03/20 |

| Analysis | 1 day | Mon 30/03/20 | Mon 30/03/20 |

| CHAPTER 5 case study 1 | 10 days | Wed 1/04/20 | Tue 14/04/20 |

| Introduction | 1 day | Wed 1/04/20 | Wed 1/04/20 |

| Background | 1 day | Thu 2/04/20 | Thu 2/04/20 |

| SCM practices | 2 days | Fri 3/04/20 | Mon 6/04/20 |

| Factors that influence inner organisation structure in case study | 3 days | Tue 7/04/20 | Thu 9/04/20 |

| factors that influence performance | 2 days | Fri 10/04/20 | Mon 13/04/20 |

| summary | 1 day | Tue 14/04/20 | Tue 14/04/20 |

| CHAPTER 6 case study 2 | 10 days | Wed 1/04/20 | Tue 14/04/20 |

| Introduction | 1 day | Wed 1/04/20 | Wed 1/04/20 |

| Background | 1 day | Thu 2/04/20 | Thu 2/04/20 |

| SCM practices | 2 days | Fri 3/04/20 | Mon 6/04/20 |

| Factors that influence inner organisation structure in case study | 3 days | Tue 7/04/20 | Thu 9/04/20 |

| factors that influence performance | 2 days | Fri 10/04/20 | Mon 13/04/20 |

| summary | 1 day | Tue 14/04/20 | Tue 14/04/20 |

| CHAPTER 7 Analysis, discussions and findings | 26 days | Tue 24/03/20 | Tue 28/04/20 |

| CHAPTER 8 conclusion and recommendations | 4 days | Wed 29/04/20 | Mon 4/05/20 |

| CHAPTER 9 Recommendations for future research | 2 days | Tue 5/05/20 | Wed 6/05/20 |

| CHAPTER 10 Report making | 60 days | Mon 24/02/20 | Fri 15/05/20 |

The project is subjected to complete with in 11 weeks schedule. The chapter breakdown is necessary to complete the project within the schedule time. The critical path is selected with start time and end time.

The above Gantt chart is prepared by using MS PROJECT software including all chapters which mentioned in above table. The total weeks are used in this project is 11 weeks estimated the work starts from week 0.

6 SUMMARY

This chapter contains research background on UK subcontractors, research questions, aims and objectives, study scope and project schedule which also been discussed before in structure of thesis. The next chapter 2 and 3 presents literature review on supply chain management and inner organisational structure.

CHAPTER 2 SUPPLY CHAIN MANAGEMENT

1 INTRODUCTION

An introduction to the research was provided in the previous chapter. The definition of Supply Chain Management (SCM) is discussed in this chapter from the generic SCM and the literature on construction management. Before presenting literature on the main features, the emergence of SCM in the construction sector is discussed. The benefits of strategic SCM activities are highlighted as a tool for cooperative involvement with companies further down the construction supply chain as well as improving the low-trust culture in the construction industry. Therefore, this chapter sets the stage for further exploration of the relationship between strategic SCM activities and inter-organizational trust dynamics in the construction supply chain. This chapter contributes to objective one of the research.

2 SUPPLY CHAIN MANAGEMENT CONCEPT

In this section, the different views of SCM concept is explained with aims of presenting a definition of concept. Based on that, SCM then discussed from operational and strategic perspectives.

2.1 DEFINITION AND OVERVIEW

The concept SCM is constantly used in fields of logistics and management of different operations (Cooper, M. C., Lambert, D. M., & Pagh, J. D, 1997) with some unclear recommendations (Chen, I. J., & Paulraj, A. 2004). The need to provide lower prices, quality goods and improved customer service in the 1980s led to the emergence of the SCM model as a result of intense global competition (Cooper, M. C., Lambert, D. M., & Pagh, J. D, 1997). The first appearance of the term ‘supply chain management’ is in 1982 (Oliver, R. K., & Webber, M. D. 1982) when it was used to emphasise inventory reduction both within and across companies (Cooper, M. C., Lambert, D. M., & Pagh, J. D, 1997). In the 1950s and 1960s, manufacturers in the U.S. had used mass manufacturing to cut costs and increase profitability, and had paid little attention to developing supply chain partnerships. When manufacturing companies started experimenting with just-in-time (JIT) and Total Quality Management (TQM) strategies as a way of increasing quality, manufacturing performance and distribution in the 1980’s, the importance of strategic and cooperative partnerships became major evident because there was often little inventory to buffer scheduling and production problems.

In the 1990s the increasing trend in market globalisation, intensified competition, high inventory cost and the need for better quality, manufacturing efficiency and customer service was further increased. This has allowed mutual collaboration between producers and a number of high-quality suppliers who have jointly adopted product design and development practices, and efforts to improve costs, quality and service. Business process reengineering (BPR), which included redesigning business processes to minimise waste and improve efficiency, also gained popularity during this same time, but then suddenly died down as it became synonymous with downsizing (Wisner, J. D., Tan, K. C., & Leong, G. K. 2014). It was at this point that, after its earlier appearance in the 1980s, SCM quickly gained popularity as a tactic for businesses to gain competitive advantage. Since then, SCM has continued to gain prominence in recent years due to a increasingly globalised market context, driven by timing and quality-based competition as well as increased environmental uncertainty (Mentzer, J.T., DeWitt, W., Keebler, J.S., Min, S., Nix, N.W., Smith, C.D. and Zacharia, Z.G. 2001). (Chen, I. J., & Paulraj, A. 2004) indicated that the idea of SCM is mostly informed by various viewpoints such as quality control, product management and integrated logistics, manufacturing markets and networks, with a greater emphasis on consumers or stakeholders.

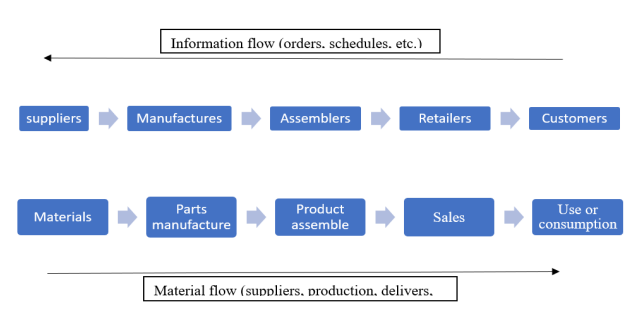

SC’s which are involved in various networks of different organisations, in different ways which result in better product or service delivered to customer or client (Christopher, M. 1994). The SC’s for various material and manufacturing organisations is as follows (Vrijhoef, R. and Koskela, L. 2000):

Thus, SCM can be defined as the application of a management philosophy by an organisation to organise these networks of upstream and downstream relations with other organisations by exchanging goods, information or services with the goal of generating value for the customer (Christopher, M. 1999). As stated by (Cooper, M. C., Lambert, D. M., & Pagh, J. D, 1997), SCM was also described as integrating the major business end-user processes through original suppliers of products, services and information adding value to customers and other stakeholders by the International centre for competition excellence, now known as the World Supply Chain Forum. The SCM is defined as the business process from one supplier to other supplier which satisfies the original product requirements and services that adds value for stakeholders and customers (Cooper, M. C., Lambert, D. M., & Pagh, J. D, 1997). SCM is the basic step for very business to enable the SC’s as one entity and advantage for long-term competitive (Wisner, J.D., Tan, K.C. and Leong, G.K. 2011). The concept of SCM is divided into two perspectives (Ganeshan, R. and Harrison, T.P. 1995) 1) Operational SCM 2) Strategic SCM.

2.1.1 OPERATIONAL SCM

The operational SCM is mainly related to concept of logistical foundations. It deals with logistical functions that consists of materials procurement, dividing these materials into products and distribution of these finished products to customers (Ganeshan, R. and Harrison, T.P. 1995). This operational SCM gives additional value to SC’s to increase the sales for organisations and also it will reduce the customers order times and minimise the cost ( Bowersox, D.J., Closs, D.J. and Cooper, M.B. 2010). It includes critical coordination of activities such as order management, warehousing and storage, demand forecasting, material handling, and contact with logistics (Lambert, D. M., & Stock, J. R. 1993). (Green, S. D., Fernie, S., & Weller, S. 2005) also revealed that this aspect of SCM focuses on understanding more effective ways to handle the distribution of products, resources and knowledge through the entire supply chain. This is with the aim of significantly reducing inventories and controlling efficiently the relationship between manufacturers and the production line (Vrijhoef, R., & Koskela, L. 2000).

According to (Vrijhoef, R. and Koskela, L. 2000), the four roles of SCM in construction involves:

- There is no any disturbance in workflow due to labours and supply of materials.

- To reduce the costs which are related to business, lead time and inventory.

- There is no any technical defaults in construction site with activities related to SC’s.

- To achieve management of integration and SC’s and reduce the production of site.

2.1.2 STRATEGIC SCM

According to (Tan, K.C., Lyman, S.B. and Wisner, J.D. 2002), to achieve quality, customer service and success for every organisation has to implement strategic SCM. The concept of strategic SCM is defined as it is driven as a firm by surroundings within the SC’s (Cox, A. and Ireland, P. 2002) and strategic relations developed with in the organisations (Green, S.D., Fernie, S. and Weller, S. 2005). This strategic SCM is less dominant when compared to operational SCM in SCM research.

3 IMPLEMENTATION OF SCM IN CONSTRUCTION

SCM as previously mentioned from the manufacturing sector, has gradually gained prominence in the construction sector as part of the spread of JIT and TQM (Saad, M., Jones, M. and James, P. 2002) and BPR approaches (Wisner, J. D., Tan, K. C., & Leong, G. K. 2014). The changing competitive construction environment has led the industry to start learning and implementing ideas, especially from other manufacturing industries (Tookey, J. E., Murray, M., Hardcastle, C., & Langford, D. 2001). The same as the rise of SCM in the manufacturing sector, it was slowly adopted as a collaboration of JIT and TQM as strategies for increasing performance in the construction supply cycle (Saad, M., Jones, M. and James, P. 2002). This progressive growth of the SCM in the construction industry was also attributed to the pressure to reform alternative methods and innovative systems that could increase productivity (Morledge, R., Knight, A., Grada, M., & Pryke, S. 2009).

Progress toward SCM in construction can also be tracked in the evolution of procurement approaches between the 1960s and 2000s, as well as how such evolutionary changes influenced relationship types (Saad, M., Jones, M. and James, P. 2002). Building has been dominated by traditional single-stage procurement since the early nineteenth century, marked by short-term and adversarial relationships, fractured procedures, and strongly separated functions and roles. In the 1960’s, however, new methods of procurement started to emerge in response to rising consumer needs (Edum-Fotwe, F. T., Thorpe, A., & McCaffer, R. 2001). Many of these constructive procurement improvements were motivated by well-informed and experienced construction clients (Tookey, J. E., Murray, M., Hardcastle, C., & Langford, D. 2001), and new methods such as two-stage tendering, construction management, contract management and design and build (D&B) have since evolved from these client-led development efforts. Sometimes these procurement strategies involve a re-configuration of partnerships, positions and power differentials in the construction supply chain. Project-specific partnership in the 1980s and strategic partnership in the late 1990s–where the focus on long-term business partnerships–continued to signal further progress towards SCM in construction.

A significant milestone in this evolutionary phase in the UK construction industry was the UK Ministry of Défense’s (MOD) ‘Building Down Barriers’ initiative which demonstrated the move toward best value approaches (Holti et al., 1999; Cain, 2004). In 1997, two pilot projects were awarded to prime contractors AMEC and Laing as an initiative to develop working principles for integration of the construction supply chain. The goal was to create long-term partnerships that could boost value and efficiency, rising underlying costs, and encourage trust, openness, and teamwork for those involved. Here, the MOD’s approach to construction procurement stressed the incorporation of the supply chain and single point obligation (Potts, K. 2008).

SCM gained prominence in the industry by showing that a multi-faceted system based approach is required in order to efficiently and easily manage complex supply chain networks to achieve competitive advantage through cost-reduction and productivity in an increasingly globalised market (Vrijhoef, R. & Koskela, L., 2000). The need for a system-based management approach is often due to the dynamic nature of the supply chain development and the inconveniences of previous collaborative efforts. These are listed below:

3.1 NATURE OF CONSTRUCTION SUPPLY CHAIN MANAGEMENT

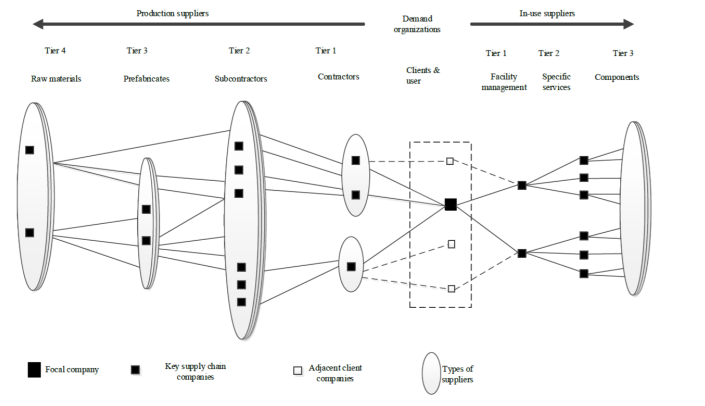

In comparison to the manufacturing sector, the supply chain structure of the construction industry is much more complex, as a typical construction project requires a network of interactions between manufacturing suppliers, demand organisations and in-use suppliers spanning various levels as shown in figure

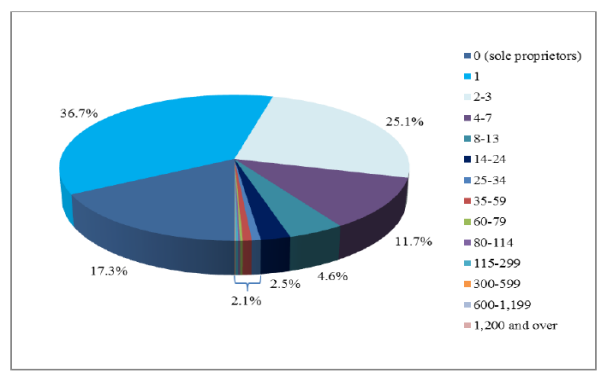

In the United Kingdom, for example, the construction sector has few head contractors and many subcontractors. And there has been a proliferation of large numbers of small firms and self-employed employees who rely on comparatively more on head contractor firms for work via subcontract agreements.

Building statistics Annual 2013 data from the Office for National Statistics (ONS) showed that 17.3% of UK construction companies had a sole proprietor, 36.7% had just one employee, while an additional 25.1% worked for up to three employees during the third quarter of 2012. As shown in below Figure, only 2.1% employed more than 25 men. Although some large companies–particularly M&E contractors–operate as SCs under a main contract, it is undeniable that small to medium-sized enterprises (SMEs) remain the driving force of the UK construction industry through subcontracting practices.

3.1.1 THEORY OF SUBCONTRACTING IN CONSTRUCTION INDUSTRY

(Vrijhoef, R., & Koskela, L. 2000) addressed the need to step away from conventional approaches to the management of building supply chains because it was inadequate due to the fact that head contractors increasingly rely on their labours and materials, usually 75-90% of building work by value, on the other actors within the chain (e.g. suppliers and SC), (Chiang, Y. H. 2009, Segerstedt, A., Olofsson, T., Hartmann, A., & Caerteling, J. 2010). This firm nature of the construction sub-contracting is also due to the specialised nature of some building works (Yik, F. W., Lai, J. H., Chan, K. T., & Yiu, E. C. 2006). In construction, experienced sub contractors are required. In addition to the necessity of subcontracting specialist building works, more common tasks, such as concrete reinforced, brickwork and interior design are subcontracted in a same way to plan a function effectively and to meet variable labour requirements. Winch, G. 1998) showed that growth in the British construction industry’s labour-only subcontracting was the result of a strategic choice by builders to emphasise the flexibility in relation to productivity as a competitive advantage.

The reasons for construction subcontractings have been outlined by (Manu, P., Ankrah, N., Proverbs, D., & Suresh, S. 2013)

- The potential to optimise labour flexibility.

- The capacity to negotiate labour cost reduction.

- Encourages faster completion of tasks.

- Ability to reduce doing hazard activities.

- Ability to transfer financial risk.

- Ability to change product according to people needs.

- Reduction of workers compensation cost.

Subcontracting has helped to ensure organisational and managerial flexibility and to provide specialised services in the construction industry, they have also played an important role in the industry’s lacklustre work (Chiang, Y. H. 2009). A major cause for poor efficiency, protection and health (Manu, P., Ankrah, N., Proverbs, D., & Suresh, S. 2013) are reportedly as multilayered subcontracting activity. Factors such as poor coordination, insolvency of subcontractors and under-standard work quality must all be tackled (Yik, F. W., Lai, J. H., Chan, K. T., & Yiu, E. C. 2006), as they affect productive construction projects. To manage these dynamic networks of supply chains, a system-based approach is required rather than linear approach. For these factors, the construction industry has taken up a range of supply chain measures and the need to improve efficiency (Vrijhoef, R., & Koskela, L. 2000).

4 IMPLEMENTATION OF SCM IN CONSTRUCTION

The implementation of SCM in construction is unique with large number of clients, head contractors and subcontractors with different views that has to satisfy the needs of the client. To implement the SCM in construction sector to improve the performance benefits (Akintoye, A., McIntosh, G., & Fitzgerald, E. 2000). There are two strategic SCM forms to implement in construction sector (King, A. P., & Pitt, M. C. 2009) are 1) Client – centric SCM model and 2) Contractor – centric SCM model.

4.1 CLIENT-CENTRIC SCM MODEL

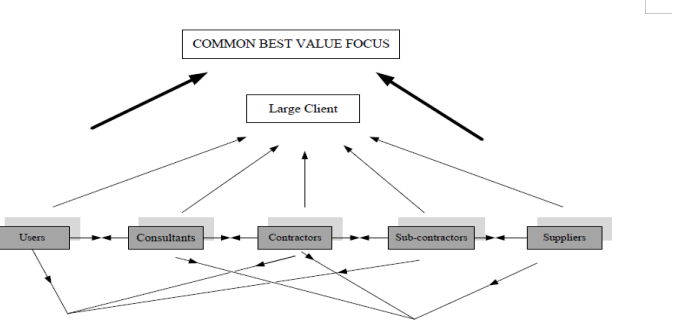

The implementation of client – centric SCM model plays a crucial role in construction management (Briscoe, G. H., Dainty, A. R., Millett, S. J., & Neale, R. H. 2004) because client dictate the organisation and production management (Tookey, J. E., Murray, M., Hardcastle, C., & Langford, D. 2001). Thus, it leads to increase the successful implementation of SCM for client leadership. The large value clients maintain a goodrelations with contractors to extract a ultimate value of appropriation (Green, S. D., Fernie, S., & Weller, S. (2005). The sample model is shown in below figure.

According to (Kumaraswamy, M. M., Anvuur, A. M., & Smyth, H. J. 2010), the above figure is the sample client – centric SCM model.

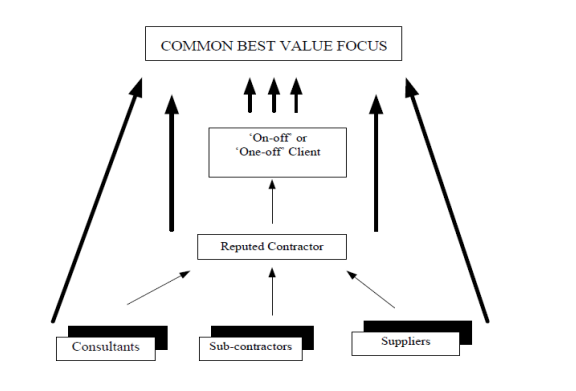

4.2 CONTRACTOR-CENTRIC SCM MODEL

The implementation of contractor – centric SCM model in construction sector is to create strong potential between client and contractors with certain SC’s. King, A. P., & Pitt, M. C. (2009) suggested the head contractors with large organisation size to make SCM a reality in construction management. According to (Kumaraswamy, M. M., Anvuur, A. M., & Smyth, H. J. 2010), the strategy of SCM focus on one – off or on – off clients as shown in below figure.

In recent times, the development of relationship in construction sector in UK have head contractors to increase their role by managing stakeholders with collaborative working (Karim, K., Marosszeky, M., & Davis, S. 2006), thus it leads to head contractors create their SCM strategies to manage suppliers and SC’s.

5 SUPPLY CHAIN MANGEMENT PRACTICES

The different SCM practices are more strategic and still evolving day by day. There are practices listed below collected from the journal (Mentzer, J. T., DeWitt, W., Keebler, J. S., Min, S., Nix, N. W., Smith, C. D., & Zacharia, Z. G. 2001).

- Orientation of SCM

- Management of supply base

- Supply chain assessments

- Long – term relationships

- Supply chain performance

- Continuous performance improvements

- Supply chain motivation and reward

CHAPTER 4 REASEARCH DESIGN AND METHODOLOGY

1 INTRODUCTION

In this chapter, the research design and methodology for the analysis are discussed. The chapter begins by discussing different philosophical and methodological positions in the research phase before discussing philosophical positions and methodology. There is also description of the investigation method including study design, data collection, data analysis, evaluation phases and framework. The chapter also highlights ethical considerations that have been maintained in the course of the study. This chapter is intended to achieve the objective 3 of research: to investigate the strategic management of supply chains (SCM) of head contractors and their effect on inter-organizational structure.

2 RESEARCH PHILOSOPHY

The process of designing and conducting research always starts off from philosophical theory with practical effects (Saunders, M. N. 2011). While the research philosophies are latent (Creswell, J. W., & Poth, C. N. 2016), it is still important to define and address the subject while setting the framework for the researchers analysis (Ponterotto, J. G. 2005). The researchers role on the nature of reality (ontology), how the researcher understands what is understood (epistemology), and the role of the researchers principles in research design and behaviour (axiology) are three philosophic issues that are taken into consideration in this study.

3 RESEARCH METHODOLOGIES AND METHODS

Methodology refers to the study method and procedures are naturally arises from the perspective of the researcher on ontology, epistemology and axiology (Ponterotto, J. G. 2005). There also a combination of quantitative and quality research (Ponterotto, 2005), which arises from the above philosophical positions, and also they are two categories of research methodologies (Creswell, J. W., & Poth, C. N. 2016). All of the specific research approaches are focused on objective and subjective ontologies as well as on epistemology. Quantitative research methods refer to research projects that discuss research problems with numerical and objective measurements. This is also consistent with deductive explanations (Creswell, 2009) when concepts or conclusions that are operationalized and subject to extensive empirical testing are developed in advance.

However, qualitative approaches include research methods that investigate definitions and causal interactions by using text and not numerical data. Qualitative approaches comply with inductive reasoning where empirically testable theories are not available (Creswell, J. W., & Poth, C. N. 2016).

3.1 QUANTITATIVE METHODS AND ITS APPROACH

The focus of quantitative research is on testing theories by analysing the relationship of variables. There are two major approaches to quantitative study, experiments and surveys while less specific studies can also be carried out (Creswell, J. W., & Poth, C. N. 2016). These research approaches include numbers and sections evaluated with statistics (Runeson, P., & Host, M. 2009). The quantitative data is collected by two ways 1) experiments and 2) surveys.

3.2 QUALITATIVE METHODS AND ITS APPROACH

Qualitative approaches to study are structured to investigate the significance people to add individual and social issues. Data are analysed primarily through categorization and sorting (Runeson, P., & Host, M. 2009) in terms of quality analysis in terms of phrases, definitions, photographs, and diagrams. The five key qualitative research practises identified by Creswell (2012) are taken into consideration in this review. The five qualitative methods are listed below table

| Description | Narrative research | Phenomenology | Grounded theory | Ethnography | Case study |

| Focus | Explore individual | Understanding experiences about phenomenon | Develop data in grounded theory from field | Describe and interpret a culture or social group | In depth analysis of a single or multiple cases |

| Disciplinary origin | Anthropology | Psychology | Sociology | Cultural anthropology | Political science |

| Data collection | Interviews and documents | Statements, meanings, theories | Interviews | Observations and interviews extended to fieldwork | Multiple sources including documents, interviews |

| Data analysis | Stories and historical context | Statements, meanings, general descriptions | Open, axial, selective coding, conditional matrix | Description, analysis, interpretation | Description, themes, assertions |

| Narrative form | Detailed picture of individuals life | Description of essence of experience | Theory | Description of cultural of group or individual | In depth case study |

4 METHODOLOGY POSITION FOR THIS RESEARCH

The research design process involves inter linkages between conceptual principles, investigative techniques, and research methods implemented in a research project (Creswell, J. W., & Poth, C. N. 2016). First, this analysis is in the subjective ontological context mentioned in above section, since the concept of trust itself is a subjectively rooting psychological phenomenon in the minds of the individuals being studied. Second, the study focuses on deeper definitions in terms of head contractors (HCs), supply chain management (SCM) activities and how these impact inter-corporational trust dynamics during projects from these subjective perspectives. This epistemological interpretative position coincides with the ontology of many subjective realities adopted.

The interpretative epistemology often shows that the researchers’ principles and beliefs will affect interpretations of all these facts. However, steps are taken to reduce the errors in study. In addition, while the importance of properly understanding how much the researcher’s beliefs impact the study process–reflection (Corbin, J., & Strauss, A. 2014), the researcher in above section, personal history, pre-school convictions and motives and how they have influenced the study. These studies are carried out by qualitative research strategy.

4.1 RESEARCH METHOD FOR THIS RESEARCH

In order to further explain the choice of a qualitative research approach, various qualitative and quantitative research methods have been evaluated to determine the most appropriate for answering the research questions presented in this study.

Specific variants of experiments on trusting games have been used in confidence studies. These trust games are designed to examine the effect of trust in decision-making based on decision making (Fetchenhauer, D., & Dunning, D. 2009). For example, the studied by Evans and Krueger (2010) examined the depths of decision making based on potential risks (egocentric cost and profit assessments) and likelihood of reciprocity (based on a parties tentation to fail). Risk and tentation were regulated orthogonally by means of a single index of two risk levels: low risk and high risk alongside specific payoff’s. Online participants were recruited against virtual partners for 10 rounds of the match, which showed that trust is affected considerably by risk and reciprocity.

(Hartmann, A. and Caerteling, J. 2010) have also used a joint experiment on choice to determine the relative value of price and confidence in construction subcontractors procurement. Head contractors were choosen for the two different rates of price, technical knowhow, quality and cooperation between four SCs, 3 known and 1 unknown.

There were no problems with this implementation of trust-based experiments in protected study. (Hartmann, A. and Caerteling, J. 2010) acknowledged that there are still major flaws regarding the limited number of attributes and the assumptions remains shortening. Since the purpose of this study was to examine within context the complexity and scope of the relationship between SCM practises and trust dynamics of HCs rather than causal relationships between these two variables, it became clear that it was not possible to follow an experimental research design. Furthermore, exploring this trust factor from HC and SC perspectives on the context of an existing construction project would have been challenging under experimental conditions.

Surveys were also considered, as these were widely used in trust research. Trust scales were used to measure various levels of trust among construction practitioners (Wong, P. S. P., & Cheung, S. O. 2004). It is difficult to arrive at a single measure capable of capturing the dynamic and multi-dimensional essence of inter-organizational trust and these survey-type studies have also revealed that other contextual factors are likely to account significantly for variances in trust interrelationships with other relevant variables (Laan, A. 2009). The rigid design of these survey instruments often addresses trust as static rather than as a dynamic concept; restricting within context a rich exploration of inter-organizational trust.

Narrative and phenomenological studies have also been studied as they are best suited to capturing individuals and groups experiences. The study focused not only individuals but also other situational concerns that could affect trust requirements as it emphasis on SCM activities and interorganisational trust dynamics. The purpose of this study was to establish no holistic overview of interorganisational trust but rather to understand how it functions within the framework of various strategic SCM activities adopted by HCs. Narrative analysis was inappropriate. Since phenomenology cannot allow outside of personal consciousness considerations (Groenewald, T. 2004), this study was also not considered relevant.

Basic theory work was often considered because of its use as an inductive theory source of observations and interviews. However, the study did not seek to create a theory on SCM or inter-organized trust (IOT), it had to be discounted as a best-in-class strategy, rather it was aimed at providing a comprehensive and in-deps account of how SCM strategies have been implemented in HCs practices.

Ethnographic work may also have been a possible method for investigating and shaping the SCM cycle over the course of projects. However, this choice was not made possible by the common use of observation by participants and the time-based nature of ethnographic studies. In all such meetings, there were also issues with access to the nature of agreements between HCs and the supply chain as an active participant. The research also aims to better understand how different SCM techniques influence the creation of inter-organizational trust more than one ethnographic research would have required. In short period of time for the analysis, this would have been almost impossible to achieve. A case study approach for carrying out these analysis was the most suitable option.

4.2 JUSTIFICATION FOR THIS SELECTED RESEARCH METHOD

Case study research is appropriate when researchers intend to undertake in-depth concept for instance the development of inter-organizational trust in the supply chain of the HC. Researchers promoted a deeper understanding of the nature of the inter-organisational relationship (Laan, A. 2009) through longitudinal-style studies. Quantitative studies have also indicated the importance of context in the creation of interorganizational trust (Laan, A. 2009). Bijlsma-Frankema, K., & Costa, A. C. 2005) have therefore argued that when studying the development of inter-organizational trust, the context within which inter-organizational relations are built should directly taken into consideration. Therefore, case research indicates the avenue for studying in the sense of the supply chain of HC, the inter-organisational trust starts building cycle for time. It is also given the ability to blur and intertwine borders between the development of interorganized structure and the context in which supply chain relationships are formed.

Secondly, the risk of triangulating several sources of evidence by case studies (Proverbs and Gameson, 2008) is an advantage. This approach enables methodological triangulation (different methods for the processing of data) and triangulation of data sources (different sources of evidence) (Yin, R. K. 2013). Through interviews, passive observations and record analysis the methodological triangulation has been achieved. Triangulation of data sources was accomplished through interviews with various workers of the same source group (HC and SC staff), which put together different views on the same issues.

In addition, case study design is considered as ideally suited to address the questions most commonly asked in this review. The key research questions on ‘How’ HCs are responsible for controlling their supply chains and on ‘How’ they are evolving in the supply chain of the HC are ideal questions for this case studies.

5 RESEARCH PROCESS

There are four research phases are involved in this research 1) research design phase, 2) data collection phase, 3) data analysis phase and 4) framework phase as shown in figure below

5.1 RESEARCH DESIGN PHASE

The three main objectives for this phase are 1) literature review, 2) case study design and 3) preliminary workshop

5.1.1 LITERATURE REVIEW

Chapter two included a summary of the literature on strategic supply chain management. Before making a distinction between the operational and strategic SCM viewpoints, a description of SCM and its historical evolution in the manufacturing sector were given. The rise of strategic SCM was further explored in the construction field. It has been discovered that the customer-led SCM project-based research emphasis has gained more coverage than the contract-led organising SCM. Although empirically lacking, SCM implementation guided by the contractor was suggested to have possible implications for creation of the inter-organizational relationship between HCs and SCs. Then chapter 3 explored the idea of inter-organizational trust, analysing the literature from various theoretical and academic viewpoints to expose its multiple facts.

5.1.2 CASE STUDY DESIGN

For this research, a multi-case study design (Yin, R. K. 2013) has been adopted as a way to explore the inter-organisational trust dynamics in various UK HCs supply chain. The operational variations in the structuring and structure (Ankrah, N. A., & Langford, D. A. 2005) of building organisations are likely to represent variations in SCM practices with various impacts for the creation of inter-organizational trust. Thus multiple case study approach is the best way. These several case studies included several embedded analysis units. (Yin, R. K. 2013) proposed that study on case studies can adopt epistemological orientations both actual and relativistic or interpretative. However, the most suitable case studies design for the answering of the research questions posed in this study is defined as interpretative. The aim was to better understand and optimise the experiences from selected cases as indicated by Stake (1995), provided that the participant researchers were able to represent several realities and significances on the HC’s SCM strategy and the consequent impact on the interorganized trust dynamics.

5.2 DATA COLLECTION PHASE

The major sources for data collection in this phase are 1) observations, 2) semi structured interviews and 3) analysis of documentary. The details of example for both case studies are mentioned below table

| Case study 1 | Case study 2 | |

| Semi structured interviews | SCM manger – 1Project contractor – 3Subcontractors – 7 | Quantity surveyor -1Contractor – 2Subcontractors – 4 |

| Observations | 2 pre meetings | X |

| Analysis of documentary | Workshop slides, subcontract package list, procurement rules, procurement status. | Profile of company, SCM document, subcontractors |

5.3 DATA ANALYSIS PHASE

The analysis is done in two stages in this phase are 1) With in analysis and 2) Cross analysis.

5.3.1 WITHIN ANALYSIS

Details of every case were evaluated in a within analysis. This started with importing data into Nvivo from each case. The data imported included interview transcripts, field notes and related case documents. (Miles, M.B. and Huberman, A.M. 1994) have followed the three-pronged quality assurance strategies they are 1) data reduction, 2) data display and 3) verification. Thus, these three steps were part of the internal examination.

5.3.2 CROSS ANALYSIS

(Miles, M.B. and Huberman, A.M. 1994) concluded that cross-case review is very valuable, as it increases the common comprehension of cases. A cross-case review was carried out in this study using the case-in-case approach to establish similarities and variations between the two cases and to aim for explanations. During this cross analysis, the thematic conceptucal matrices are identified. These combined displays help the finding and drawing of stronger conclusions of trends in the two cases.

5.4 FRAMEWORK PHASE

A SCM oriented trust building system based on cross analysis findings was built in this phase as shown in Figure. This structure included core SCM activities by HCs that emerged in the various dimensions of inter-organisational trust and the behavioural impacts of the projects resulting from these trust dimensions. The aim of the framework was to help the HC project team and the SCM staff understand the impacts of their policy and project decision-making. Subsequently this process was evaluated from the viewpoints of selected participants participating in decision taking in the supply chain. The aims of this evaluation process for participants to define the effect and interpretations of these features were understood. These detailed framework analysis and evaluation is carried out in chapter nine and ten.

CHAPTER 5 CASE STUDY 1

1 INTRODUCTION

The previous chapter mentioned the research methodology and design of selected UK head contractor (HC) organisations and their effects on the inter-organizational trust formation for the investigation of strategic supply chain management (SCM). In this chapter, it deals with findings from the case study 1. The history and results of the SCM practices of case study 1, the explanation of trust, the factors affecting trust and the practical implications of trust are discussed. This chapter refers to objective four of the research, which aims to examine the degree and functionality of inter-organizational trust within the framework of the HC-SCM practise.

2 CASE STUDY 1 BACKGROUND

In this case study, the brief history about the company, the case study history that includes brief details about the client, the case studies summary and research participants background is important.

2.1 BACKGROUND OF THE COMPANY

Masterton holdings LTD in the United Kingdom was founded in 1874. Since then they have become a global building company with various branches across Europe. It has consistently been ranked as one of the leading ten UK construction companies by annual turnover in the UK construction industry. It’s turnover is about £1.8 b, employing 28,000 employees in different construction sectors worldwide. Alpha has a network of seven regional branch offices in the UK to promote closer communication with its customers in the UK. This study was supported by the West-Midlands regional office of Masterton holdings.

2.2 PROJECT DESCRIPTION

In the East Midlands area, this project consisted of the relocation of an existing civic centre to a city council. The present structure need redevelopment to the space and activities. The consumer therefore planned for a valuation of £30.5 million. The aim was to maintain the building’s iconic external facade and renovate the interior in accordance with modern standards and increased space requirements. The project therefore included renovation and new building work to be performed for a contract period of 15 months.

To achieve this, a new section containing pile walls, 350 pile structural steel frames, pre-cast concrete floors and single ply sheet tops was demolished into the courtyard. The current building layout requires a new layout. The existing façade also required cleaning and replacement of brick and stonework. As a design and build (D&B) contract, they won the job by making a competitive tender, growing the project’s commercial value. When data collection started in February 2012 at project level, work was advanced into the ninth month, and 55% of construction activities were completed. The project consisted of about 29 main subcontract packages. The features are as shown in table below.

| S.No | Characteristics | Company 1(Masterton holdings LTD) |

| 1 | Nature of project | Construction |

| 2 | Location | East midlands |

| 3 | Nature of works | Building of houses |

| 4 | Client type | Public sector |

| 5 | Type of selecting contractor | Competitive tendering |

| 6 | Arrangement of procurement | Build, design |

| 7 | Sum of contract | £30.5 million |

| 8 | Subcontractors | 29 |

3 SCM PRACTICES

After the analysis, Eight SCM practices are outlined as follows 1)Orientation of supply chain, 2) Management of supply base, 3)Assessment of supply chain, 4)Long tern relationships, 5) performance of supply chain, 6)Supply chain IT system, 7) Continuous improvements in performance, 8) motivation of supply chain and its rewards. The table below is discussed their practices

| S no | SCM practices | Strategy and their practices |

| 1 | Orientation of supply chain | To reward contractors who perform well with and to rising contractors chances to pursue projects.Approx 90% of the workload per year to subcontractors.Supply chain manger is adopted. |

| 2 | Management of supply base | Around 5000 subcontractors are used nationally each year.The large supply chain base is categorised into four groups by supply chain.Subcontractors well aware of their position in the supply chain at each stage, well organised with allocation of contacts by each sub-contractor.High coordination level with subcontractors of the group top. The connectivity level further decreases into the category. |

| 3 | Assessment of supply chain | Wellness, architecture, job policies, financial stability and contract conditions in supply-chain interviews and audits.Collection of relevant references, commercial inspections and visits to the office where necessary. |

| 4 | Long term relationships | Approximately 50% of contracts placed nationally with high class subcontractors. Formal long-term subcontracting agreement only signed with subcontractors in category one. |

| 5 | Performance of supply chain | H&S performance evaluation, work level, system cooperation, contractual cooperation, financial cooperation, work supervision and design feedback.H&S scores were shared and discussed with all project sub-contractors and other scores are shared and discussed with sub-contractors of class one.IT systems keep updating performance scores. |

| 6 | Supply chain IT system | Quick to use the in-house team IT system.Carry trading details subcontractors, supply chain status, project objectives, output reviews and e-tendering supports.Contact information for each subcontractor in the database of the main contact. |

| 7 | Continuous improvements in performance | Annual review meetings with subcontractors of category one to evaluate results, identify areas of progress as well as the positive as well as the negative aspects of the agreement.Each subcontractor will be assigned the contact person. |

| 8 | motivation of supply chain and its rewards | Best result of annual award for subcontractors.Priority tendering on the basis of the supply chain status of subcontractors.Payment scheme for 30 days. |

3.1 ORIENTATION OF SUPPLY CHAIN

Company generally subordinates about 90% of its workload to SCs, making selection and management crucial to project success. It does not actually build anything, the construction manager clarified that it was responsible during the project for choosing the right SCs and for managing them safely, productively and effectively. Consequently, they has an SCM Team that is managed with other SCM personnel by the Supply Chain Manager, responsible for implementing SCM Policy and strategically involving SCs. For example-“ They have got their faces in the supply chain, they have [supply chain manager] who’s engaged with subcontractors, so I think that’s good, because that’s how they’re asking you about anyone, that’s your touch if something goes wrong, but not like a lot of businesses do. So it’s organised and I definitely believe it operates better than most other enterprises.”- head of contracts. The above statement is collected from preliminary interview with supply chain manager.

3.2 MANAGEMENT OF SUPPLY BASE

Approximately 5,000 SCs is used in company’s supply chain base each year for different projects. The four levels of these SCs in the database were divided. SC’s of the highest level (limited to around 250 in the UK) were those who had developed a long-standing relationship with company over years and contributed strategically to their company. The supply chain manager explained the categorization framework as follows-“Growing area reviews the effective subcontractors for which they worked, and the very well-performed subcontractors moves to category 2. This is about 20% of the supply chain. Of the 20%, who are working for us and through an interview process, we develop a partnership and an agreement that we shall work together closely as well as an audit of our documents and our quality are in Category 1. The other people are category 3 and category 4.” This statement collected from interview with supply chain manager.

3.3 ASSESSMENT OF SUPPLY CHAIN

Before registering in the supply chain database of the company and subsequently assigning a project to work, all SCs must undergo rigorous supply chain assessments. This assessment was generally started by means of events involving buyers, where SCs from a local area are needed. The supply chain manager explained this process-“ If we have our work in an city, local companies will contact us and then the right firms will be given a chance to do the ordinary recruitment where we can pursue references, review ads, visit their offices and then there more tested but not to exclude them. It is a way of ensuring that the projects are viable”. The above statement shows the strict controls company carries out when a SC is found high risk since it never worked on its project. Such inspections are used to understand how SCs conduct their business (visit their offices, financial status and technical skills).

3.4 LONG TERM RELATIONSHIPS

By signing an agreement on working closely together, company emphasised the development of long-term relations with its category one SCs. During the supply chain workshop, this ambition was illustrated when it was revealed that Category I SCs were given the opportunity to price any upcoming job. 54% of orders were issued for level One SCs in 2012 on average and that percentage for the Midlands region is even higher (84%) as shown in table below. The focus of company on promoting long lasting supply chain relations with its class one SCs.

| No of orders | Order placed | %spend in category 1 | |

| London | 64,627 | 46,530 | 76.30 |

| Western | 37,584 | 26,793 | 60.35 |

| Midlands | 56,583 | 49,405 | 95.54 |

| North west | 31,743 | 7,756 | 43.32 |

| North east | 49,549 | 20,583 | 61.62 |

| South east | 76,084 | 34,464 | 45.51 |

| Average | 54,985 | 34,939 | 65.42 |

3.5 PERFORMANCE OF SUPPLY CHAIN

The project team regularly assessed the success of SCs in all of the company projects. The supply chain manager clarified that four times a year every project site has SCs and these scores have been reported directly by the site management team in the supply chain data base. This allowed anybody inside company to review SC’s output in live projects. The evaluation of performance was carried out on various aspects i.e H&S, work standards, policy enforcement, contractual cooperation, financial cooperation, work supervision, and design feedback. However, during the project, the SCs were not notified about these results.

3.6 SUPPLY CHAIN IT SYSTEM