Introduction

Home cinema speaker stands have been in use for several years. Their applications utilize specific requirements that are known to improve the quality of the produced sound. Studies have shown that the characteristics of the sound from various sources are affected by the objects around. This is due to the effects of produced echo. Reflected sound waves do not only affect the quality of the sound but also other mechanical properties like wavelength and amplitude of the successive waves. In order to minimize these defects, speaker stands have been invented. They raise speakers slightly above the ground.

Task 1

Roles and functions of Speaker Stand

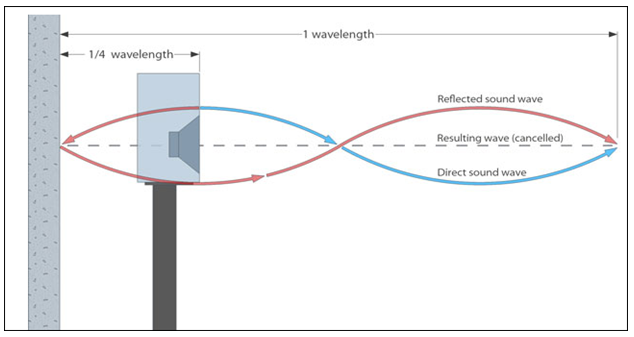

Not hearing enough bass through screens? The separation between the room limits and speakers hugy affects bass execution (Ellis 2014). Speakers are increasingly omnidirectional at low frequencies, which mean bass waves emanate every which way, causing a thundering hubbub. Bass waves transmit in reverse from the speakers, around the wall before listener and when they hit the stopping point, they are reflected. At the point when the reflected sound wave bounces off the wall joins with the source sound wave originating from the speaker, it makes acoustic obstruction. In the event that the speaker is one quarter wavelength from the wall for a specific recurrence, wave crossing out happens at that recurrence. This causes a repulsive plunge, indent or invalid in the recurrence reaction (Parmentier 2013).

As speakers are drawn nearer to the wall, the scratch-off indent in your recurrence reaction moves to higher frequencies. That is incredible news in light of the fact that higher frequencies are progressively directional (they emanate less vitality in reverse), and they are simpler to oversee utilizing acoustic treatment. For the most part, a hole of 0 to 8 inches (0 to 20 cm) between the speakers and front wall is a decent beginning stage to limit shading caused by SBIR. Be that as it may, check the amplifier specs for a prescribed least separation.

For instance, Genelec prescribes a base separation of 2 inches (5 cm) to consider enhancer cooling and back opening sound radiation. At close separations, 4 inch thick absorptive acoustic boards behind the speakers may help tame the abrogation score. Broadband bass snares would be better. As speaker-wall separate builds, treatment turns out to be less pragmatic. The adequacy of assimilation behind the speakers likewise relies upon speaker directivity. In case one is utilizing dipole speakers (utilized in some hey fi setups), ingestion will help more than if one is utilizing monopole speakers. Most speakers are monopole (Leyendecker et 2014).

Setting the speakers near the front walls helps drive them, giving more yield and less contortion. Notwithstanding, it likewise causes low racking, a lift in the bass reaction (similar to the vicinity impact that happens when one puts a sound source near a directional receiver). One can achieve this without much of a stretch agreeable this with EQ. A few speakers have limit gain remuneration control, which gives one a chance to apply an estimated adjustment. Even better, a person can utilize a calibrator to make an EQ bend that precisely makes up for the limit impacts that is being encountered.

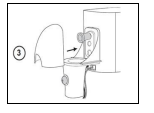

Figure 1: Effects of walls to sound waves

When speaker stands are used in a case like the one illustrated above, the reflection of the sound waves can be avoided. Sound clarity is therefore is achieved properly. As much as stands are commonly known for combatting reflections that take place at the initial stages, they also help in the elimination of the decoupling that takes place between the speakers and the floor itself. This system or technique is called mechanical isolation.

Task 2

Technical drawing

This section has been covered in the software file as shared

This was the redesigned speaker stand that was suggested. The stand had the following geometrical features and dimensions

Base

The new speaker stand had a trapezoidal base as shown in the figure above. This was used to increase the stability on the ground. The distance between the two parallel sides was taken as 12cm. The alpha and beta values were taken as 60 and 75 degrees respectively.

Lower stand

The lower stand section was made from a cylindrical rod of low carbon steel. The diameter was taken as 20mm while the height was taken as 60mm.

Upper stand section

This component was properly modified. It has a diameter of 20mm

It has been made from a cylindrical rod of aluminum alloy. Unlike the previous design that had a twisted bent, this component was made straight .The length was taken as 40cm.The elimination of the bent allowed for direct transmission of the weight of the speaker.

Collet

Unlike the original design, the collet in this new design was adjusted to a length of 10mm for maximum grip. It had a diameter of 20.5mm

Universal Bracket

There was no modification on this component.

Task 3

Material components

Base

It has been made by the use of the cast iron. The base of the design has a radius of 70mm. This material has proper properties of casting and also damping of vibration. Considering this part will be in touch with the ground most of the time, it is best suited for the same job. There is bore at the Centre which is linked with the lower section of the stand.

.

Figure 2: Grey Cast Iron base (Skelton 2016).

This materials that is cast iron has good wear resistance. Other desirable characteristics that made it applicable for the base include the following:

Strength: Cast iron has higher strength at decreased expenses. They additionally have higher quality and malleability and are stiffer than unadulterated iron. The quality of cast press is the thing that makes it a serviceable material for different ventures. It has a low dissolving point and more noteworthy ease.

Castability: Cast iron is utilized in a variety of enterprises as a result of the simplicity of its castability. The cast iron can be formed into different shapes and sizes dependent on the modern needs. The expense of generation and the negligible utilization of instruments make it a feasible assembling material (Tsiami et al 2014).

Machinability: Cast iron can be effectively machined into conclusive items. The properties of a metal like hardness, elasticity and microstructure adjust its machinability. Consequently, it tends to be utilized in various enterprises for assembling various items.

Durability and low cost: Cast press spares huge amounts of cash in the long haul. It requires next to zero upkeep for bound to happen. Utilizing cast press in businesses can take out pointless substitution. Further, cast press items can be incorporated into existing frameworks, in this way limiting the expense of substitution. Cast press is likewise more moldable than different metals.

Collet

The collet is basically used in the connection of the two sections of different pieces. The span standard designed to be 8mm in length. The fastening property requires materials with the properties of the Polyamides which include the following:

Has more resistance to bases and acids that can easily cause corrosion thus affecting the loosening process.

Has low friction coefficient

Resistant to higher temperatures that may cause expansion and subsequent loosening of the joint.

Figure 3: Collet (Skelton 2016).

Universal Bracket

It is use for enclosing the bear pints of the attachment. This particular section is under the influence of the vibration forces or impacts. ABS compound has Butadiene that is actually responsible for the increased toughness and strength impact (Sánchez 2013). ABS plastic is made utilizing an emulsion procedure which includes the three segments which are Acrylonitrile Butadiene and Styrene. At the point when these monomers are assembled, acrylonitrile builds up a polar fascination with different atoms, therefore making the polymer intense. Additionally, within the sight of butadiene, physical quality is added to the plastic on account of a procedure generally known as elastic toughening (Butadiene is really elastic and not plastic). This procedure and technique are regularly utilized for assembling ABS plastics; in any case, the extent of the monomers can differ. By including more Acrylonitrile for instance the plastic will be more grounded and harder.

Figure 4: Universal bracket (Skelton 2016)

Lower Stand Section

Figure 5: Lower Section (Skelton 2016).

The lower Stand section has been has been made of low carbon steel material .It is a cylindrical tube that is threaded at its ends. Its standard length 64cm .Since it is the part that links the upper section of the stand or the upper components of the stand with the base, it must be able to have capability of damping vibrations (Dawson 2017). The other desirable characteristics of low carbon steel that were utilized included the following:

Cost Effective:

The minimum costly of all steel types, numerous ordinary articles are made utilizing low carbon steel, including auto-portable suspension, bike outlines and a lot of cookware (Smith 2017). The mystery behind its moderateness is its carbon content; extending anyplace somewhere in the range of 0.16% and 0.29%, this center purpose of the carbon check go implies it’s sufficient for some occupations without being lavishly malleable. At the point when it’s required in robust applications, it tends to be created all at once with a far diminished expense than other different steels, with results that unquestionably can’t contend with.

Material can be welded:

Not at all like high-carbon steel, can low carbon steel be properly welded without breaking its structure. Because of the explicit properties of the metal, electric flows travel through it without misshaping the composition of the material. This is diverse to, state hardened steel, where unique procedures are required so as to weld the metal to an expert standard. This eliminates cash spent both on worker hours and electrical expenses; with a basic complete to round up its simple manufacture.

It is ductile:

Ductility is the proportion of how much a material can be plastically twisted by stretching, without break. Materials that are solid in such manner can go over 15% before they are for all time distorted and unfit to return to its unique shape. Low carbon steel imparts great organization in such manner to copper and thermoplastics, ready to curve, extend and have generally expansive powers connected to it, making it simpler to frame, shape and weld (Graber 2012).

It can be carburized

The significant drawback to low steel is that it has a generally low rigidity, which means it’ll break more effectively under pressure than different steels. Fortunately, there is an answer. Carburising is a warmth treatment process in which either iron or steel is warmed, with carbon freed as it deteriorates (Hainge 2014). At the point when cooled by means of ‘extinguishing’, the surface is presently hard, while the center stays delicate and extreme. This is an incredible method for upgrading the quality and wear properties of generally economical steels, notwithstanding enhancing its exhaustion quality.

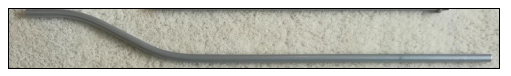

Upper Stand Section

Figure 6: Upper section (Skelton 2016).

This is the component that connects the lower stand section with the upper components of the speaker stand .It has a twist angle of 160 degrees at the neck. In order to make the stand lighter, there was need to use a metal that can provide the required strength but with addition of little weight. Aluminium alloy thus was preferred for this particular part because it has the following features that were needed in the design:

High Strength to weight Ratio

According to strength to weight ratio, aluminum normally outdo other materials. This is why it was clearly preferred for this particular part. It could support the heavy speaker at greater strength while at the same time remains light for portability.

Resilience Under dynamic and static loading

Most of the alloys of the aluminium show elastic behaviour when they are subjected to dynamic and static loading conditions .This imply that they possess the ability to resume the size and shape which is actually okay when flexible strength is needed.

Much Strength at low temperatures

As the temperature of the surrounding reduces the strength of the aluminium alloy increases. This happens without the loss of quality hence suitable for this kind of applications.

Corrosion Resistance

When exposed to air, there is normally a formation of a thin oxidized film on the surface that actually protects the material from corrosion. When this layer is actually scratched even several times, the protection continues. This means that this part of the speaker stand will remain strong even if it is attacked by the corrosive agents.

Task 4

Manufacturing Techniques

Base-In this case the ore is heated in the blast furnace together with the limestone and coke. This process actually deoxidizes the ore and removes the impurities hence molten iron is achieved. The molten iron is poured into the molds of a circular shape to give base structure that is circular as shown. Boring is then done followed by internal threading process (Audio & Wiring 2012).

Lower Stand section-After the treatment process of the ore, molten low carbon steel is poured into a mold that has a cylindrical shape and with the specific dimensions. Other modifications on the component are done by the use of the external operations (Audio & Wiring 2012).

Upper Stand Section-Molten aluminium that has been purified is poured into a mold that has the shape of the stand as required. The mold will then duplicate the pattern that is desired. Other operation like parting and filing are just used to get a proper finish (Audio & Wiring 2012).

Collet-This too has been made from a plastic polymer. The selected plastic polymer is subjected to high temperatures. The molten plastic is then poured into a mold with the specific dimensions and patterns of the required collet (Audio & Wiring 2012).

Universal bracket-It has been made from ABS class of plastics. A molten plastic of desirable characteristic is poured into a mold that has specific shape and pattern. Finishing operations like cutting and internal threading is done using specific tools (Audio & Wiring 2012).

Task 5

Redesign of the Speaker Stand

The process of the redesign of the speaker stand involved modification of specific parts. The chosen redesign features includes having triangular base and straight.

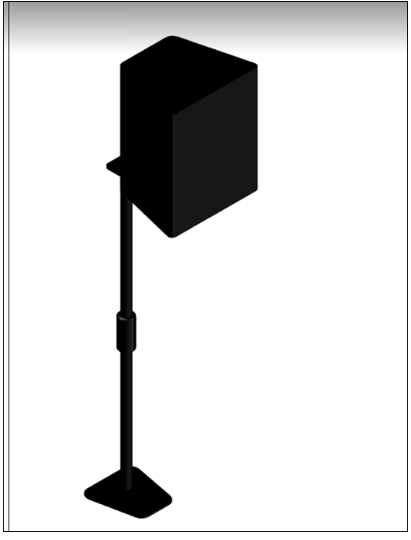

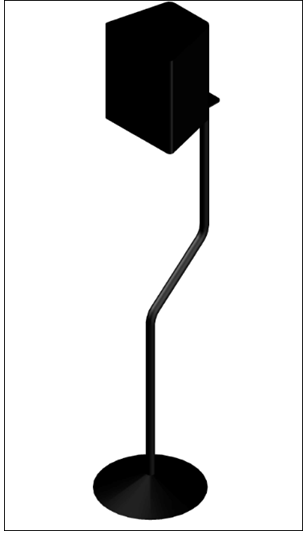

Figure 7: Original and redesigned speaker stands a and b respectively (Skelton 2016).

The circular base has been associated with lots of vibration effects due to its flatness with the ground .In order to reduce this kind of the vibration; the base has been redesigned into triangular shape thus reducing the effects of the vibrations.

The other modification in the design was done on the upper stand section. The bending section in the initial design produced a tilting effect when the speaker was in use. In order to reduce this effect of the tilting, a straight stand has instead been preferred to allow for the perpendicular and direct transmission of the load from the speaker to the base direct (Jang 2012).

Conclusion

Manufacturing processes of the home cinema speaker stand employs various techniques and use of materials that provide different tastes of the products. The performance of the home cinema is greatly affected by the nature of the stand used. Although stand is used to prevent reflections of the sounds from nearby opaque objects, it contributes to the durability of the speaker as well. This is because the speaker is not in direct contact with the ground. Continued use of speaker stand has led to inventions of specific polymers that have vibration combating capability. Such materials have been used in design of the base.

REFERENCES

Audio, M. R., & Wiring, S. (2012). Security Systems.

Dawson, S. (2017). At the present time. Connected: Home+ Business, (Aug 2017), 60.

Ellis-Geiger, R. J. (2014, October). Cinema sound facility design for higher education. In Audio Engineering Society Convention 137. Audio Engineering Society.

Graber, C. E. (2012). U.S. Patent No. 8,111,836. Washington, DC: U.S. Patent and Trademark Office.

Hainge, G. (2014). Three non-places of supermodernity in the history of French cinema: 1967, 1985, 2000. Playtime, Subway and Stand-by. Australian Journal of French Studies, 51(2-3), 234-249.

Jang, D. U. (2012). U.S. Patent Application No. 13/213,766.

Leyendecker, P., Zwing, R., Abelard, F., Morvan, P., Desert, S., & Doyen, D. (2014). U.S. Patent No. 8,903,217. Washington, DC: U.S. Patent and Trademark Office.

Parmentier, M. (2013, October). A Special Room for 3D Audio and Ultra High Definition Video for Quality Assessment of Future TV. In Audio Engineering Society Convention 135. Audio Engineering Society.

Sánchez-Escalonilla, A. (2013). From Hoover to Bush Jr.-home and crisis scripts in US social cinema. Jump Cut. A Review of Contemporary Media, 55.

Skelton, P. (2016). Take it with you. Connected: Home+ Business, (Dec 2016), 56.

Smith, K. W. (2017). KWSnet Shopping: Electronics Index.

Tsiami, A., Rodomagoulakis, I., Giannoulis, P., Katsamanis, A., Potamianos, G., & Maragos, P. (2014). ATHENA: A Greek Multi-Sensory Database for Home Automation Control uthor: Isidoros Rodomagoulakis (NTUA, Greece). In Fifteenth Annual Conference of the International Speech Communication Association.