0 Introduction

In this assignment, the selected production system is the transport system for the Frankfurt Airport. This international airport is located in Frankfurt, one of the largest cities in Germany. It is being operated by Fraport and serves as the main hub for Lufthansa includes of Lufthansa CityLine and Lufthansa Cargo. In Germany, this airport is the busiest airport based on passenger traffic. The airline industry is providingtransportation services to the passengers, and also cargo therefore; the main production system for the airline industry is a transport system (Frankfurt-airport.com 2017). The selected system is an enabler to achieve economic growth as well as development.

The report is based on critically appraise the inventories and assets into the production system. The key operations of the selected transport system are discussed with presenting a logical operational flow. There is also an illustration of two points where the organization’s delivery system may fail to align its operational performance measures.A lean approach is utilized in the production system to reduce failings. Finally, the findings are analyzed to which the lean approach would assist the production system with operational measures.

2.0 Management of inventories and assets within the production system

The paper discusses the development of the airline industry as a branch of the transport system and highlights the system characteristics of the airline sector. The transport system has grown into a major sector of the global economy. Frankfurt Airport is looking to reduce the freight spend while maintaining the service levels. Implementation of a transport system means the integration of dynamic order allocation in transportation planning processes. The order allocation functionality is incorporated with automatic shipment planning (Bamfordand Forrester 2010). Due to Frankfurt Airport’s success with the transport system, it improves transportation data to enhance freight management capabilities (Greasley 2013). The company has enhanced their transportation platform so that they can offer order along with inventory management dealt withservices. The company is improvingtheir transportation services by optimization across inventory.

The transport system manages the inventory and assets of the selected organization by an implementation of a warehouse management system which can track product to lot level and permits accurate sequencing. The company move to vendor managed inventory model by the development of warehousing relations with the suppliers. With the transport system, the company can reduce freight expenses as the system can provide savings by analytics along with optimization (Johnston and Clark 2008). It also tracks deliveries in real time by viewing the pilots along with shipments. It provides to create effective route schedule by providing the pilots with effective routes. The system provides improved passenger service levels with an ability to monitor on-time performance. An online portal is provided where the customers can see where the shipments are along with informing the passengers. Therefore, the transport system provides increased customer services as they have the ability to access shipment and information of freight when required. With a constant flow of both incoming along with outgoing inventory, the warehouse is required as part of logistics processes. It creates a record of orders along with track where it is located in the warehouse and in transit (Mardaniet al. 2016). Finally, the transport system of Frankfurt Airport increases the efficiency of a supply chain as it has the ability to track the pilots, inventory and airline processes which allow the company to increase its productivity and provide savings to the users.

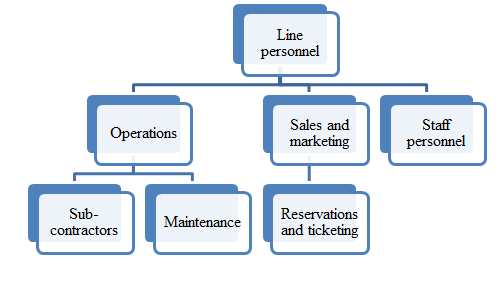

Figure 1: Functional chart of the airline and relationship among

the business functions

(Source: Mardaniet al. 2016, pp-379)

The above figure shows the functions of the airline industry which are managed through the use of the transport system. The system can improve operations, drive the business, provide better services to the customers and manage the inventory and assets (Belobaba, Odoniand Barnhart 2015). It assists the company to move freight from origin to destinations properly moreover cost effectively. Therefore, by an implementation of a transport system in the airline industry, the company can gain more productivity and achieve profitability so that it can gain a value to their business in Germany. Using the SWOT analysis, the strategic decisions are to be analyzed for the airline industry such as the following.

The strong areas of Frankfurt Airport in managing the inventories and assets in their transport system are:

Strength of service:The company increased its propensity to fly which has provided immense growth into the industry.

Low-cost service:The airline services bring an opportunity to fly at a low cost than their competitors.

Deal with advanced technology: From the fuel-efficient transport to advanced as well as an automated process, the technological advancement makes the industry a faster-growing industry.

The weak areas of Frankfurt Airport are:

Lack of IT infrastructure:The government of Germany is trying best to build a proper IT infrastructure for airports, even there is a lack of technical experts those can structure the airport.

Expensive flight tickets: The airline company is providing with cheap offers, even the flight tickets are expensive as well as required pricy disbursements.

The opportunities areas are:

Technological advancement:The airline industry is facilitating some technical services such as automated ground processes, and fuel-efficient aircraft and others.

Increase revenue: The in-flight customer’s services are increasing, and value-added products have raised the revenue as the customers are paying discretely.

The threats areas are:

Economic downturn: The economic slump provides an effect on the growth of the company as it will disturb leisure travel and business travel.

Increase in the cost of fuel:As the fuel-efficient airlines are emerging, the airlines are based on fuel. When there is an increase in cost, it will make flights expensive (Holloway 2017).

3.0 Key operations involved in chosen production system

The transport system is processing to achieve the required business functions and operations. The system helps the company to gain economic health along with a quality of life. The management of transport operations is being comprised of tracking as well as managing the aspect of maintenance of airline, fuel costing, routing, mapping, and air-to-ground communication, handling of cargo, selection of carrier and management of accounts (Slack, Brandon-Jones and Johnston 2013). The transport operations are encompassed aspects of the logistics chain and at heart of service enterprise. Air transportation is important components into the transport system. The benefits of the lean approach are that it is used of less building space, suppliers required to meet with inventory demands from the buyers.Lean approach is based on effective customer relations as they are involved meeting with the requirements of loyal customers on a scheduled basis. It is easier to customize the products and production processes when to select buyers (Greasley 2013). Following are detailed of key transport operationswhich are used to create a competitive strategy into air transport and development of information system such as:

Tracking and managing the aspect of maintenance of airline: The transport system can track the route of the pilot and ensure a safe as well as correct functioning through the flight. The aircraft maintenance is periodic inspections which are done in aircraft after a certain amount of time. The airline industry performs a continuous inspection program (Bazargan 2016).

Fuel costing: It is one of the biggest expenses for the airline industry. On average, Frankfurt Airport accounts for 29% of fuel costs of operating expenses and 27% of the airline industry revenue. The industry is benefited from the decline of oil and fuel prices (Kleymann and Seristo 2017).

Routing and mapping: The transport system can create animated and interactive route maps of the flights showing the destinations of flights to the passengers so that they can know the exact time required to reach the destination. The passenger can add icons, texts on top of the map and then connect them with the lines. Each of the icons is clickable and contained information inside (Kleymann and Seristo 2017).

Air-to-ground communication:This communication channel is done by means of which people in the ground,as well as airborne vehicles, are communicated with each other. The staffs on the ground communicate with the pilots in the air. The ground controls the use of visual aids for providing signals to the pilots in the air (Wensveen 2018). There are also portable radios which are to be placed in the flight so that the pilots can able to communicate back to the ground. The flights are outfitted with a new radio, internet, and video capabilities along with GPS systems.

Handling of cargo:The handling agent can table of the air cargo at the airport to as well as from the aircraft. It is based on the kind of goods, destination, and delivery type (Ford, Paparoidamis and Chumpitaz 2015).

Selection of

carrier: Selection of the right carrier is

required to get satisfied services from the airline company. The system helps

the passenger to select the carrier by providing user-friendly web-enabled

tracking tools. This system provides with proper status messages of the

worldwide shipping data in real time (Williams 2017). Booking, as well as

documentation, are electronics which will facilitate worldwide shipping

processes.

4.0 Failure of organization’s delivery system to align operational performance measures

The delivery system of the airline system sometimes failed which provides a huge effect on the operational performance measures. The air transport system is one of the delivery systems for the passenger as it moves the passengers from one place to another. The first point is a failure in the flight plan system causes widespread delays into the time of flights (Pattonet al. 2011). The computerized system for the loading flight plans is failed, which may cause widespread traffic delays of 90 minutes, as well as there, are cancellations of the flights. The second point is that the failure means that the automated system at regional facilities is not processing information to the pilot present in the flight. The result is that it causes delays as the flight personnel is not forced to input flight information manually (Stevenson 2009). This type of failure is attributed to software configuration problems into the airline infrastructure. The disadvantages of the lean approach are that it is based heavily on the suppliers as those can provide products for manufacturing processes. The problems are related to airline delays, quality errors on part of suppliers and others. The vendors are not able to supply parts and products on a strict schedule. Implementation of the lean approach requires higher cost as a training of employees is required in this case. The purchase of machinery for the airline is increasing efficiency, and the cost of a changeover (Helmreich and Merritt 2017).The flight delay is a service operation failure which provides an effect on the satisfaction level of travellers.

The level of customer satisfaction is low for the service failures and the customers are blaming the service providers for the delivery system failure. The airline cost structure increases in cost along with a decrease in demand. The failures can provide a negative impact on the increase in oil price, drop in growth of GDP, political uncertainty and also natural disasters. The airline’s industry becomes safer and efficient with more profitable with the management team (Slack, Chambers and Johnson 2007). The problems that are affecting the airline industry are not gone away. In fact, it is becoming more complex. Sometimes, the internal and external operations of the airline industry are affecting operational performance. The main concept of any airline industry is the satisfaction of the customers. The goal of the company is to achieve a higher level of customer satisfaction and enhance relations with the customers. The loyal customers are a profitable group for the airline industry those are used of that particular airline for traveling purposes.In order to avoid dissatisfaction and keep the customers satisfied, the service providers are getting second chance to improve the organizational performance is service recovery (Shaw 2016). It is required for the service providers that they should employ effective service recovery strategies to alter consequences of the system failures. Due to failures, it provides a huge effect on the performance and therefore the passengers are not wished to use their airline services. It reduces the profitability and the company should face a huge operational loss. When it comes to operating properly, then the industries are directly impacting customers such as aviation. A delayed flight is caused problems when the passengers are tried to make the connecting flights.

5.0 Lean approach utilized in the production system to reduce failings

The airline industry is facing problems in their airline operations and therefore the company is going to implement a lean approach to reduce failings into the business operations. The lean approach is defined as rapid in addition to the smooth flow of the goods and information, reduction of the wastes from the business. Into the airline industry, long lead time, as well as higher inventory levels, are required for the global supply chain. The global supply chains are long, sales forecasting are accurate as well as managers are content with delays. The lean approach is used to reduce and eliminate the waste and ensure on time that the failures are mitigated (Odoni 2015). The capacity of air travel is growing immensely along with competition. The lean approach is focused on cutting out the waste in the process. Six-sigma is focused on the elimination of defects in existing processes and designed as possible. The goal of this lean approach is the elimination of variation, append flexibility along with putting the systems that can exploit the employ of human talents (O’Connell 2018).It provides the organization with more control over the quality of the final product and service.

The airline industry is involved with the lean approach with the addition of issue of safety; the airline industry is aimed to improve the satisfaction of passenger. The operational failure areas are delayed flights, missed connections, longer layovers, lost of luggage in addition to canceled flights (Ford, Paparoidamis and Chumpitaz 2015). The weather is one of the issues beyond the operation failures of airline. Most of those issues are being reduced and eliminated by applying of lean six sigma approach. Following are the steps of the lean approach which are used to reduce the operational failure such as:

Collection of data: It is the first step of lean methods to gather data on existing operation of the airline industry to determine areas which require improvement as well as identify the wasteful process steps. Monitoring of the passenger traffic flow, the total number of delays, cancellation of flights, instances of the lost luggage are the operational issues, while the airline leaders can obtain straight feedback from the passengers through survey and provide the information that they are required on what works and does not work (Belobaba, Odoniand Barnhart 2015).

Delay in departure: The application of lean reduces in addition to eliminating the duplications and delays by breaking the process into sub-processes, identification of details of each business operations and time of each activity (Duran, Gurel and Akturk 2015).

Wastage of employee time: One of the wastes which are identified in lean is employee time. The issue is related to determine the right level of staffs both into customer services and maintenance. It leads to check the passengers, understaffed baggage and mechanics are tried to find a part rather than work on the plane. The lean approach helps to improve the employee time and quality of services(Odoni 2015).

6.0 Key findings on lean approach assistsselected production system

The airline industry is continued to face of competitive as well as cost reduction pressures while the company is striving to make the industry safer. Due to an increase in the technical reliability of the airline industry, a lean approach is used to make improvement in operational performance measures. The lean methodology integrates quality with its existing management processes which attain effectiveness in addition to reveal the safety performance in observance with new aviation safety regulations (Helmreich and Merritt 2017).Following are three findings to which the lean approach is assisted into the airline industry such as:

Improvement of inventory: The Frankfurt Airportis adopted of lean management approach using just-in-time production which allows the company to reduce the inventory, get better over the accurateness of catering services in the airline and raise of entire consistency of stocks (Chao and Li 2017). The company is adopted workflow practice where the employee is responsible to stock drawers improves the quality of their stocking processes.

Low cost and fare: The lean approach helps to reduce the cost of running operations of the airline and reduces fare for the customers. The lean practice is used to reduce the time that the airline is on the ground (Burghouwt 2016). The crew can request the passengers to pick own magazines as well as trash that do not reduce ground time but helps to reduce the cleaning expenses. The lean strategy is used to diminish boarding time by calling the passengers that are seated at various portions of the airline at various times at the time of boarding processes to get a better entire efficiency of business processes. Frankfurt Airport has lowered the cost and improved reliability of the airline services through this particular strategy. Therefore, among the employees, there is a higher airline in addition to employee productivity (Kleymann and Seristo 2017).

Enhance the customer service: The lean approach is used to improve the customer services, and then the airline company is included with the check-in system which would increase by segmenting the passengers. Most of them are handled based on routine as well as rest is by service agents (Stolzer 2017). This lean technique is allowed the company to match with staffing with the arrival of passengers and monitoring varied processing time. It assists to eliminate causes of slowdown as well as a set protocol to deal with uncontrollable events like cancellations because of weather conditions.

Refine the baggage handling: The handling of baggage is an issue which is associated with the airline company. Poor baggage handling is taking a lean management. The lean strategies are used to reorder with the workflow of the baggage handling as well as reduce the time which is required for bags to arrive at the luggage carousel. The airline industry is not delivering baggage with higher reliability along with speed (Lawton 2017). Frankfurt Airport improved baggage handling through utilization of lean six sigma strategy. As the plane is on blocks, the cargo doors are being opened and bags are taken even before the passengers are started to move. The limits of operation management and lean approach are that the airline company has lack of proper IT system as lean processes are based on complex procedures like Just-in-time. There is a limitation to set up an ERP system to enable planning and strategy formulation (Johnston and Clark 2008). Therefore, it limits accurate monitoring of the system.

7.0 Conclusion

It is concluded that the transport

system of Frankfurt Airport is such that it provides

connectivity to national and international scale. It helps to generate trade,

in addition, to create employment opportunities. Into the airline industry, the

operational failures are inventory issues, low-cost fare, customer dissatisfaction,

loss of the baggage and cost overrun. Those operational failure issues provide

a huge effect on the performance of a company which leads to loss of

productivity and revenue of the company. There should be proper tracking of

airline route as it provides to create effective route schedule by providing the

pilots with effective routes. In order to overcome with the system failures,

the lean approach is used as a workflow with automated alerts as well as

notifications. It has robust search capabilities along with advanced reporting

an analytics. The lean approach

is improving customer services. The business efficiency is the goal

of continuous process improvement efforts. It is involved with elimination that

is not adding value for the customers. It is focused on quality furthermore

performance improvements.The lean approach creates efficiencies into the

airline industry. The airline improves its maintenance programs, process

related to ticketing in addition to airline design.

References

Bamford, D. and Forrester, P., 2010. Essential guide to operations management: concepts and case notes. John Wiley & Sons.

Bazargan, M., 2016. Airline operations and scheduling.Routledge.

Belobaba, P., Odoni, A. and Barnhart, C. eds., 2015. The global airline industry.John Wiley & Sons.

Burghouwt, G., 2016. Airline network development in Europe and its implications for airport planning.Routledge.

Chao, C.C. and Li, R.G., 2017. Effects of cargo types and load efficiency on airline cargo revenues. Journal of Air Transport Management, 61, pp.26-33.

Duran, A.S., Gürel, S. and Aktürk, M.S., 2015. Robust airline scheduling with controllable cruise times and chance constraints. IIE Transactions, 47(1), pp.64-83.

Ford, J.B., Paparoidamis, N. and Chumpitaz, R., 2015. Service quality, customer satisfaction, value and loyalty: An empirical investigation of the airline services industry. In The Sustainable Global Marketplace (pp. 187-187).Springer, Cham.

Frankfurt-airport.com (2017). Frankfurt Airport – Company information, Investor relations, Job opportunities.

[online]

Frankfurt-airport.com. Available at: https://www.frankfurt-airport.com/en/travel/transfer.detail.suffix.html/contact/allgemein/about-fraport-ag.html [Accessed 11 Oct. 2018].

Greasley A., 2013. Operations Management, Third Edition, John Wiley. ISBN 978-1-11997-854-1.

Helmreich, R.L. and Merritt, A.C., 2017. Culture at work in aviation and medicine: National, organizational and professional influences. Routledge.

Holloway, S., 2017. Straight and Level: Practical Airline Economics: Practical Airline Economics. Routledge.

Johnston, R. and Clark, G., 2008. Service operations management: improving service delivery. Pearson Education.

Kleymann, B. and Seristö, H., 2017. Managing strategic airline alliances. Routledge.

Lawton, T.C., 2017. Cleared for take-off: structure and strategy in the low fare airline business. Routledge.

Mardani, A., Zavadskas, E.K., Khalifah, Z., Jusoh, A. and Nor, K.M., 2016. Multiple criteria decision-making techniques in transportation systems: a systematic review of the state of the art literature. Transport, 31(3), pp.359-385.

O’Connell, J.F., 2018. The global airline industry. In The Routledge Companion to Air Transport Management (pp. 39-56). Routledge.

Odoni, A., 2015. The Global Airline Industry.John Wiley & Sons.

Patton, S., Clegg, B., Hsuan, J and Pilkington, A., 2011. Operations Management. McGraw Hill. ISBN 978-0-0771-2617-9.

Shaw, S., 2016. Airline marketing and management.Routledge.

Slack, N., Brandon-Jones, A. and Johnston, R., 2013.Operations Management, 7th Edition. Pearson. ISBN 978-0-273-77620-8.

Slack, N., Chambers, S., and Johnson, R.,

2007. Operations Management. Fifth

Edition, Prentice Hall.

Stevenson, W.J., 2009. Operations

Management. Tenth Edition,

McGraw-Hill Irwin.

Stolzer, A.J., 2017. Safety management systems in aviation.Routledge.

Wensveen, J., 2018. Air transportation: A management perspective. Routledge. Williams, G., 2017. The airline industry and the impact of deregulation.Routledge.