Introduction

For conducting this assignment work, the current food production process in a fast food restaurant, McDonald’s will be studied. In this study, the key operations of food production process will be discussed by presenting logical operational flow diagram. In order to make improvement in the business performance and increase in business efficiency, current food production system of the restaurant will be analyzed by applying concepts of lean approaches.

1.0 Critical evaluation of inventories and assets in the production system are currently managed

The selected organization in this business case is McDonald’s, a fast food restaurant in US. The organization started by two of brothers, Dick and Mac McDonald. They had started their first restaurant in California in the year 1940 (Corporate.mcdonalds, 2016). The main objective of this organization is to serve food at faster pace that will be value for money plus proper taste and quality. For purpose of this study, role of the operation manager is identified as asset in the food production system and discussed how those resources are currently operated in the business operations.

Over last nine of fiscal years, revenue of McDonald’s was achieved its peak at 28.11 billion U.S. dollars. Since the peak, there is a decrease in revenue on annually basis over last three years, hitting about 24.62 billion U.S. dollars in the year 2016 (Corporate.mcdonalds, 2016). Payne-Palacio (2016) stated that the current system of McDonald’s is based on maximize efficiency to lower the customer cost, increase in entire organization’s production and utilize economic models. McDonald’s has self-order kiosk machine such that the customer should order the food and only have to pick it up. Therefore, the company is cutting their labour cost and let the customers work for their own orders. In this way, McDonald’s raises their minimum wage by $1 over the local mandated minimum pay for the company owned restaurants. This raise is not affected franchise owned restaurants. Raise in $1 did not bring minimum wage of company to $15 per hour level. Selling in the restaurant released in least 13 months is raised to 6% internationally in past quarter, which makes the company as ninth following period of the similar stores sales growth (Corporate.mcdonalds, 2016).

2.0 Food production workflow of McDonald’s

The organization is shedding new lights on heavily criticized sourcing of food plus food processing practices. In face of growing in customer demands for transparency, the organization provides good burger to their customers as per their expectations. The organization consisted of right materials and suppliers for their restaurants (Slack, Chambers and Johnson, 2007). They have paper and boxes to wrap the burgers, cups for the soda, hot beverages and straws, bags to carry the food items, cutlery and other items. The role of operation manager is to work on financial success for the outlet as well as maintain a better reputation of the company. The operation manager ensured that they serve higher quality of food, drinks and provided better customer services. It helps the manager to better flow of their food business operations throughout the restaurant, enable to plan the cash flow and control of stock by launching a mobile app (Amorim et al. 2016). McDonald’s launched a new mobile application which attracts more customers. The customers use the application and buy food through online mode by use of attractive coupons. This application also provides nutrition information which will help to make healthier purchases. Mobile ordering is an advanced food technology application which can mark food production development well-organized. McDonald’s creates a reward loop for the customers which keep the guests to come back. It started with free food after ordering a certain amount of money. It encourages the customers to order food through mobile application.

The current food production process of McDonald is that their food items such as beef, chicken and meets are being imported and delivered from different food delivery partnership to the restaurant. McDonald’s is partnering with Uber Eats where the biggest burger chain started testing delivery to 200 locations last year. Due to this partnership, delivery is available to 5000 out of chain 37000 locations. UberEats is said to take 30% of the food delivery transaction such that they can plan for the future growth. The company is changing perception of the food delivery around world (Wang et al. 2016). Through this growing partnerships, UberEats is helping the restaurants to scale the business as well as reach new customers. The restaurants is offering delivery, now it is accounted for 10% of the sales of food in locations. Therefore, it is seen that delivery check size of McDonald’s is 50% higher than in-store check size.

McDonald’s store has being updated with modern interiors as well as Wi-Fi but there are major changes in the table services. The customers can order at cashiers and digital kiosks in which they can customize order with. In UK, new restaurants are resulted to sales growth of 8% in stores as well as 4% in drive thru. McDonald’s changed advertisements as they are offering combo meals to their customers. It helps to save money by buying of combo meals and special offers that can keep the customers updated in advertisements on television and posters on the streets (Davis et al. 2018). The company is running local TV as well as advertising to introduce the operation management concepts.

McDonald’s promoted happy meal toys program to attract the kids and focused on selling of Happy Meal Toys in place of food products. The company made their advertisements towards cartoon charters by means of short funny stories. It is about minions those are having fun eating the Happy Meals and kids those are happy as they are getting Mini Minions from the Happy Meal. It leads to increase in sales revenue to 28.11 US dollars. The company is having playground for the children in various locations, such that they can make place for the children to spend time and parents can buy more as they stay longer at the restaurant (Kato et al. 2015). McDonald’s spends most of 40% of multibillion dollar marketing budget on the marketing related to the kids.

In most of the countries, McDonald’s is opetated 24 hours food service policy, therefore there are more attractive to the customers as they can order or buy food at any time. McDonald’s has separated their store for McCafe where coffee as well as backery section is completely separated from the main store. The organization did so as those customers who are coming for gossiping and relaxing should go there and take their time as long as they want in the McCafe. In the store, the customers can get freshly coffee, tasty frappe and mouth-watering desserts and cool smoothies (Kibler et al. 2018). In most of the locations, McDonald’s provides free parking lot so that the customers are not worried about parking when they visited the store.

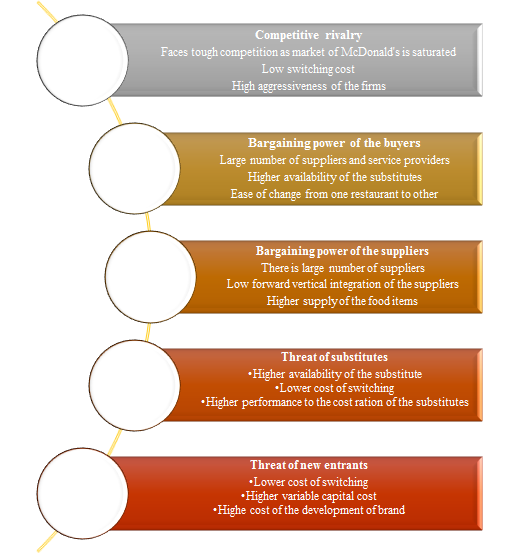

Figure 1: Porter five force model

(Source: Slack, Chambers and Johnson, 2017, pp-529)

Competitive rivalry: It is strong for McDonald’s as the restaurant faces competition among their competitors such as Jonny Rockets, Wendys Chickens, Burger King and others. Each of the players are providing same menus to the customers. The global informal eating out segment is comprised of around 8 million outlets as well as generated USD 1.2 trillion of revenues while McDonald’s has 0.4% outlets and 7.5% of sales. McDonald’s tried to offer better deals to the customers and tried to make more advertisement especially in social media sites.

Bargaining power of the buyers: It is strong as the buyers of McDonald’s have various options in the market. They can switch to other restaurant if they are not satisfied with their products (Swink et al. 2017). The buyers can protest the price increases by McDonald’s and then shift to their competitors.

Bargaining power of the suppliers: It is weak as the raw materials like chicken, potatoes that the restaurant users for their products are available through various suppliers. The suppliers are not in position to bargain with the company and not force them to increase the price (Thi, Kumar and Lin 2015). In this case, McDonald’s many switch to other suppliers with low switching cost.

Threat of substitutes: It is strong as the substitutes of meals of the restaurant are meals of other different fast food restaurants such as KFC. The bakery products are also considered as substitutes of McDonald’s products (Davis et al. 2018). Therefore, switching to other substitutes do not provide any switching costs.

Threat of new entrants: It is moderate as in the international level, there are many entry barriers. In order to become successful as McDonald’s, the competitor should create many outlets through the world that needs large capital investments plus times.

3.0 Food production workflow problems

In all over the world, there is crisis of food due to rising population and increasing usage of technology. There is huge wastage of food which can cost a huge amount of price. In current food production process of McDonald’s, there is lack of forecasting and planning which can lead to poor customer servicing (Hitt, Xu and Carnes, 2016). Due to lack of forecasting, the restaurant is facing quality problems in the food production workflow. When the quality of food items are not meet with customer’s demands, then there is lack of customer services (Cotrim, Leal and Filho, 2017). Quality is an issue as it is characteristics of food items which is being acceptable by the customers. Factors which can contribute to quality issues are unsuitable agricultural practices, reduced hygiene at phases of the food chain and deficiency of preventive controls in handling of food (Wood, 2018). When proper hygiene of items is not followed it can lead to customer service failure. The consumption of food is too high and the problem with consumption is doing waste as well as overeating. If those problems are fixed, then people would start to become hungry. Therefore, it is required to produce food, but must be focus on improving the environment.

The current food production is lead to unplanned work which leads to delay in production of food and delay and quality standards issues related to food items (Ford, Paparoidamis and Chumpitaz, 2015). In McDonald’s, food production is considered as inventory as the organization receives huge profit and makes about $8.5 billion of the operating income. Therefore, delay in the production process can lead to huge loss in their total annual revenue, profitability and operational incomes. There is no such inventory control of the food production. There is no proper optimization of food safety which can increase heath related issues (Swink et al. 2017). The food production process is not efficient and it increases of food wastage. In addition to the problems of overstocking, spoilage as well as waste, food inventory is predisposed to the cross contamination. Lack of inventory control can lead to dangers of the foodborne pathogens when it is not handled as well as stored properly.

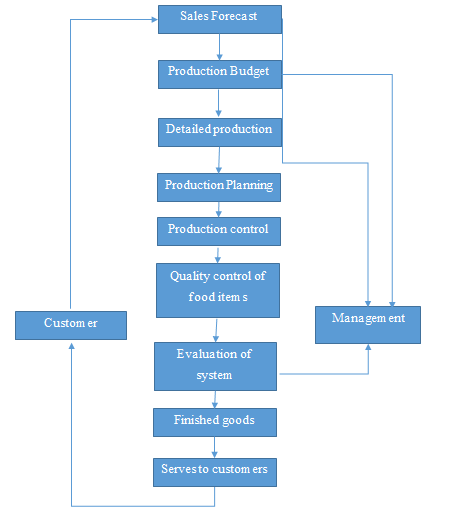

Following diagram shows the operational flow of the key operations of food production system. The goods are produced as per the demand forecast. The production system is consisted of goods which are produced based on the orders made by the customers. The goods are produced at smaller scale where the flow of production is irregular. On other hand, the goods are produced at larger scale for stocking plus selling to the customers. There are different products which are produced and the quality of the food items are controlled as well (Girotto, Alibardi and Cossu, 2015). The design of products are going to change as per size of the food product. Therefore, the food items are formed on prearranged quality standards.

Figure 2: Operational flow of the key operations of food production system

(Source: Thi, Kumar and Lin, 2015, pp-225)

4.0 Lean approach utilized in the production system to reduce failings

The main purpose of lean approach is to help people in production of food items to make improvements in the business performance. Lean approach is used in McDonald’s for increasing business efficiency, productivity as well as morale of the employee. The main objective of this lean approach is to achieve higher economic growth. It requires long lead times and variability with various reasons as well as products. In the packaging lines, the processes are being streamlined. In McDonald’s, the operation manager is responsible for daily coordination, improvement as well as implementation of the food manufacturing processes, supervising the production, development, controlling of quality besides maintenance. The manager handles the customer’s complaints, works with staffs to ensure that the customers are getting enjoyable experiences and works the floor at meal time to interact with the customers. They identified to reduce amount of employees on the production line and use them in the factory. Reduction of waste is applicable in handling of food and amount of time required over various production of food on same line (Kibler et al. 2018). The CEO of the company identified elimination of the wastes which is considered as most effective way to increase in organizational profitability and business efficiency (Martin-Rios et al. 2018). Following are the lean approaches which are used to reduce failings in the operations such as:

- Quality control

- Production levelling

- Proper inventory control

- Reduction of defects in the system

After analysing entire current food production system of McDonald’s, it is determined that the current system is wasteful as it is consumed by the Operation Manager and managed the problems by use of lean approaches. McDonald’s has maintained its position in the market by adopting of following lean approaches.

Quality control: The operation manager should make improvement in quality of the food items as it helps to maintain the customer services (Pham et al. 2015). The manager can check for the hygiene of the food products from which the food items are made up. They can also serve nutritious, higher quality of food products like fruits besides vegetables. McDonald’s started a feedback procedure where they succeed to take feedback from the customers to improve quality of food as well as food services. They also tried to provide solutions against health issues among kids (Cotrim, Leal and Filho, 2017). McDonald’s made changes in its Happy Meal Menu Thursday, as part of their plan to provide healthier food options for the children so that they can get fresh fruits and organic drinks. The company started to include apple slices in each kid’s meals. The chain also added another option squeezable yogurt consisted 45 calories with 25% less sugar as compared to yogurt options geared for the kids.

Waiting time: Usage of modern technology can reduce the waiting time of the customers. The computer system can communicate the order placed by the customers to the production staffs as soon they have placed the order (Ma, Yin and Liu, 2017). Modern cooking equipment’s plus skilled workforces prepare the food in less time and therefore the processing of the order takes very few minutes to be ready. Mobile ordering application is next food technology which can make food production process more efficient.

Proper inventory control: As per the lean manufacturing principles, McDonald’s is get rid of the inventory as it incurs opportunity cost. The organization is always meet with their customer’s demands but there is also wastage of food items. By applying of inventory management principles, it is required to access of raw materials used for producing food. Just-in-time is required to reduce inventory issues as well as develop the production of food and reduce quality defects in the food equipment’s (Cotrim, Leal and Filho, 2017). It has stock control system which helps to manage process and eliminate the wastage caused due to overstocking.

Reduction of defects in the system: There are number of key improvements in the production process of food. The best way is to create role of Operation Manager and make their position instrumental in the food production line. There is high number of quality issues of food due to non-hygienic food supply and agricultural issues. The quality standards are maintained for producing of food so that there are no health related issues.

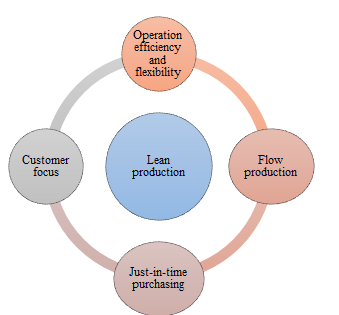

Figure 3: Lean production

(Source: Amorim et al. 2016, pp-803)

The aim of lean manufacturing is to help McDonald’s to make improvements in their operational performance. Improved performance of operations lead to lower the cost of business and it retains and invests the business on to the customers to gain extra sales volume due to lower in price of business (Kato et al. 2015). When there is increase in volume of the production, then it becomes a huge profit options for McDonald. The business will buy more products and materials to prepare the food items so that they can meet with their customer’s demands in addition to their needs. Based on the food quality, the reputation of a company is judged.

5.0 Three findings discussed extent to which the lean approach may assist production system

This section will help to identify three key findings which can discuss the extent to which the lean approach chosen in previous section can assist the food production system with aligning the operational performance measures. The main objective of McDonald’s is to deliver best quality of food items and provide better customer services by considering the added value in the current food production process (Davis et al. 2018). By addressing on following three findings, the capacity of Operation Manager is analyzed to focus on the strategic activities based on quality delivery and better customer services.

Quality control: By applying of quality management principles, the goal of this approach is to reduce the cost, quality maintenance and better customer services (Girotto, Alibardi and Cossu 2015). The lean tool is useful to optimize the manufacturing as well as food production. Over past years, the restaurant has started a journey to improve quality of food through menu by using of fresh food items in place of frozen foods and removing artificial ingredients from the classic burgers. Cheeseburgers were removed from the food option and bottle water was added as beverage options, while chocolate milk is reformulated to reduce extra sugars (Stevenson, 2009). Therefore, 100% of happy meal combinations is offered menu boards of 600 calories or less than that.

Proper inventory control: By applying the inventory management principles to ongoing food production process of McDonald’s, it will be possible to assist the food production system with align of operational performance measures (Holweg et al. 2018). Lean approach helps to get better control in inventory of McDonald which is result to yield less waste. It results to achieve higher profit margins for the business organization (Swink et al. 2017). There is less amount of waste as the machines is not broken down as much as they are used to. It will set the inventory management system by forecasting the data when the food is required to produce and when the food items are going to expire. The primary goal of lean approach is to keep the wastage at possible limit and increase speed at which the products is get to customers (Thi, Kumar and Lin 2015). The fast food restaurant is adopted of lean methods as the food products are consumable and it must be delivered to the customers in proper way (Slack and Brandon-Jones, 2018). It helps to boost morale as well as contribute to the workforces. McDonald’s should currently use of ERP system to manage their resources and make payments to the suppliers. By tracking all the information, the organization should determine when the food production will require and will finish. The customers and manufacturers are provided with importance to eliminate unrequired wastes and inventories along with value chain and shorten the lead times.

Reduction of defects: Training is required to provide to the store officers so that they can develop, manage as well as monitor entire food production processes effectively (Ketokivi and McIntosh, 2017). They can produce of quality standard documents so that the staffs can follow it for production of food. By increasing in quality of food and reducing the defects in the current system, it will allow the Operation Manager to be focused on strategic objectives like increasing in customer services and quality food items.

6.0 Conclusion

Throughout entire study, it is concluded that the business operations of McDonald’s is focused on the lean approach to increase business efficiency, food quality as well as productivity throughout application of tools for the lean manufacturing. The inventory wastage of finished goods is a problem in the food company because of unpreserved nature of the products, the food manufacturing is benefited from the lean approach. The negative consequences is adding of asset based on the personnel those are not professional to manage the inventory and assist forecasting of food production. By applying the lean approach and reducing the waste in three areas, it is identified that there are changes of improvements to increase quality of food and customer services.

7.0 Recommendations

Below are the recommendations which are provided to the management of McDonald’s so that they can make improvements in their operational performance such as:

- The organization should invest of happy meal as well as playgrounds for the kids to secure McDonald’s as the family restaurant and target kids mostly by providing a nutritional value as well as health. McDonald’s is able to lure the kids and their parents at alarming rates so that the kids get engaged in playing and their parents can relax and have breathing space over McCappuccino.

- McDonald should continue its inventory by use of just-in-time (JIT) approaches. JIT is such a production system which is used to produce kind of unit required, time required and proper quantities of food items required. Idea behind this strategy is to reduce the cost of management of inventory of the restaurant. It also helps to provide fresh foods to the customers. The strategy is helpful as the managers do regular basis stock count at end of each day to keep track of food items. It helps to check sales amount which are performed by the restaurant is first in first out. As per this strategy, it is used by McDonald’s to trade product which has reached initial and then final ones. The entire stock management is planned in such a way that just in time plus first in first out is monitored severely.

- McDonald’s started a food donation program in partnership with the Food Donation Connections to donate over 370,000 pounds of foods to the charities. The restaurants wastes like cooking oils, cardboard used for packaging and polyethylene foils are recycled to turn in new resources. The other method should use is landfill. McDonald’s should also think of sustainable packaging of their food items.

References

Amorim, P., Curcio, E., Almada-Lobo, B., Barbosa-Póvoa, A.P. and Grossmann, I.E., (2016). Supplier selection in the processed food industry under uncertainty. European Journal of Operational Research, 252(3), pp.801-814.

Corporate.mcdonalds (2016). Company Overview | McDonald’s.

[online]

Corporate.mcdonalds.com. Available at: https://corporate.mcdonalds.com/corpmcd/investors-relations/company-profile.html [Accessed 11 Feb. 2019].

Cotrim, S.L., Leal, G.C.L. and Filho, D.A.M., (2017). Management tools as a support of cleaner production implementation: a case study in a food industry. International Journal of Services and Operations Management, 28(4), pp.524-539.

Davis, B., Lockwood, A., Alcott, P. and Pantelidis, I.S., (2018). Food and beverage management. Routledge.

Ford, J.B., Paparoidamis, N. and Chumpitaz, R., (2015). Service quality, customer satisfaction, value and loyalty: An empirical investigation of the airline services industry. In The Sustainable Global Marketplace (pp. 187-187).Springer, Cham.

Girotto, F., Alibardi, L. and Cossu, R., (2015). Food waste generation and industrial uses: a review. Waste management, 45, pp.32-41.

Haksever, C. and Render, B., (2018). Service and Operations Management. World Scientific Books.

Hitt, M.A., Xu, K. and Carnes, C.M., (2016). Resource based theory in operations management research. Journal of Operations Management, 41, pp.77-94.

Holweg, M., Davies, J., De Meyer, A. and Schmenner, R.W., (2018). Process theory: the principles of operations management. Oxford University Press.

Kato, T., Nakajima, T., Saito, T., Okitsu, J., Shiga, Y. and Miki, Y., Hitachi Ltd, (2015). Operations management methods and devices thereof in information-processing systems. U.S. Patent 9,128,704.

Ketokivi, M. and McIntosh, C.N., (2017). Addressing the endogeneity dilemma in operations management research: Theoretical, empirical, and pragmatic considerations. Journal of Operations Management, 52, pp.1-14.

Kibler, K.M., Reinhart, D., Hawkins, C., Motlagh, A.M. and Wright, J., (2018). Food waste and the food-energy-water nexus: A review of food waste management alternatives. Waste management, 74, pp.52-62.

Ma, Y., Yin, Y. and Liu, Y., (2017). A holistic approach for food waste management towards zero-solid disposal and energy/resource recovery. Bioresource technology, 228, pp.56-61.

Martin-Rios, C., Demen-Meier, C., Gössling, S. and Cornuz, C., (2018). Food waste management innovations in the foodservice industry. Waste management, 79, pp.196-206.

Payne-Palacio, J., (2016). Foodservice Management: principles and practices. Pearson Education.

Pham, T.P.T., Kaushik, R., Parshetti, G.K., Mahmood, R. and Balasubramanian, R., (2015). Food waste-to-energy conversion technologies: current status and future directions. Waste Management, 38, pp.399-408.

Slack, N. and Brandon-Jones, A., 2018. Operations and process management: principles and practice for strategic impact. Pearson UK.

Slack, N., Chambers, S., and Johnson, R., (2007). Operations Management. Fifth Edition, Prentice Hall.

Stevenson, W.J., (2009). Operations Management. Tenth Edition, McGraw-Hill Irwin.

Swink, M., Melnyk, S.A., Hartley, J.L. and Cooper, M.B., (2017). Managing operations across the supply chain. New York, NY: McGraw-Hill Education.

Thi, N.B.D., Kumar, G. and Lin, C.Y., (2015). An overview of food waste management in developing countries: current status and future perspective. Journal of environmental management, 157, pp.220-229.

Wang, Z., Mathiyazhagan, K., Xu, L. and Diabat, A., (2016). A decision making trial and evaluation laboratory approach to analyze the barriers to Green Supply Chain Management adoption in a food packaging company. Journal of Cleaner Production, 117, pp.19-28.

Wood, R.C., (2018). Strategic questions in food and beverage management. Routledge.