Introduction

An example of an electroacoustic transducer is loudspeaker which is an electrical device that turns an electrical signal, carrying the audio signal, into sound. It has a basket-like frame having numerous components – a flexible membrane in the form of a cone or dome that is operated magnetically, a magnet and coil system used to produce the magnetic field, and the transportation system used to support and move the diaphragm. The production of loudspeakers involves multiple stages: It covers stages such as designing, prototyping, testing, and arriving at the last stage the large scale production. Some of the factors that are settled at the time of designing are frequency response, sensitivity and power capabilities. A prototype is then made in a small scale to see the feasibility of the created design. When testing a loudspeaker, one gets to know whether it is working fine or not since testing it gets to check on its efficiency. Once this stage is over, they go to the last step of mass production for loudspeakers.

Based on the purpose and characteristics, there are different classifications of speakers and below are some of them: The most familiar given kind is the moving magnet or dynamic, where a coil and magnet work to move the diaphragm. There is also the electrodynamic which is created from an electric current passing through a coil to develop a magnetic field. Other types are the ribbon speakers that uses a thin metal ribbon to vibrate and produce sound, and the electrostatic speakers, which employs an electro-static charge to move a diaphragm.

In actual fact, loudspeaker houses have a vast array of various conventional cloth types or modern materials namely metal mesh and fabric to utilize in improving the sound quality of the loudspeakers. Diaphragms can be as light as carbon fibre, or s as strong as beryllium and high-end suspension methods such as rubber surrounds or spiders shall help make the motion truly linear. Special practices that will ensure existence of the linear movement can also be adopted in the achievement of the performance goals. Recently, there has been a constant strive towards miniaturization of loud speakers. Mobile phones and portable music players are the examples of this development as far as the audio systems are considered. While these may not contain acoustical energy as much as large loudspeakers, these are designed to deliver power output at equally high quality. However, these speakers are considerably lightweight although their power output is not as high as that of normal speakers.

Main work

Background

This specialized project particularizes on studying how loudspeakers are assembled during their manufacturing process on a production line. This particular type of loudspeaker manufacturing has been recently upgraded by a company, thanks to the use of forged parts producing improved magnetic characteristics. In addition to the above improvements, this redesigned loudspeaker has the following advantages, which include a smaller number of component pieces and a mechanism for making feeding automatic but easy for the human operator.

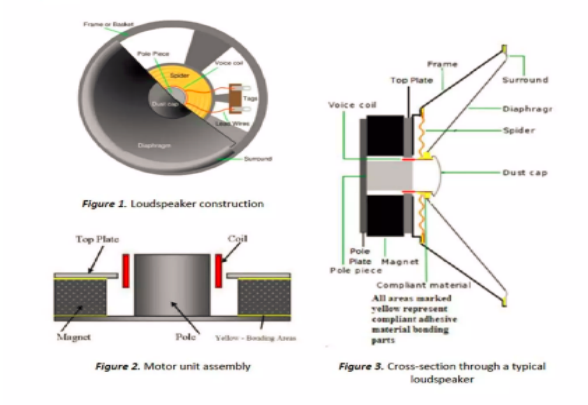

The basic parts of the loudspeaker is illustrated in figure 1. It is also important to note, that in assembled state, motor unit and voice coil look like on the picture 2. A cross-sectional view of one sort of a prevalent loudspeaker is shown in Figure 3. Full loudspeaker assembly process is shown in the following figures 4 and 5. Ideally, as many aspects of the manufacturing line should be automated as possible, but, presumably, some of the ‘soft’ elements should be assembled manually. Exploring the bibliography of books and articles that focus on the loudspeaker items and their manufacturing reveals a complex work devoted to the development of new technologies in the sphere of acoustics and manufacturing technologies. Current findings have shed more light in various facet of loud speaker design, materials and process that enhance the manufacturing process. The work by Lawrence, Allison, and Naify (2022) can be viewed as a valuable input to the existing body of knowledge because of the authors’ emphasis on modular multi-material printed acoustic loudspeakers. They have contributed new ideas to loudspeaker design specifically based on the methodology of modularity, additive manufacturing, and the mixture of materials resulting in improved acoustic performance. According to Lawrence et al. (2022) this is in line with the change that is currently evident in manufacturing from the traditional rigid systems focusing on the mass production to the flexible and more adaptable systems; the applications of this model may be seen in several contexts.

Similarly, Downey (2021) gives a brief on loudspeaker arrays and test facilities to give a perspective on active noise cancelling measurements in large volumes. Thus, this research enriches the knowledge of loudspeaker applications apart from the manufacturing and underlines the necessity of the effective testing facilities in order to evaluate and enhance the loudspeaker performance in real conditions.

Unfortunately, there is limited research on the relationship between attachment building and social inclusion to date, although Bevrnja, Imamović, and Bisić (2022) address this line of interest. They examine how the disabled persons can be made to assimilate into the transport systems through this technique known as additive manufacturing. While this study does not centre on speakers, it evidences the expansion in applications of production technologies and the influence on such groups (Bevrnja et al., 2022).

Furthermore, the unpublished work by Yang et al. (2023) propose a research prospect flexible Nano generators for microphones and loudspeakers. It will also expose progress of energy harvesting components and possibilities to influence a more sustainable self-powered loudspeaker system.

Altogether, the investigated works help to gather valuable insights into materials for loudspeaker-related products and their production; testing facilities; and the general impact of manufacturing innovations made in the field of loudspeakers on society. The synthesis of these findings provides a sound platform for the subsequent phases of the project that involves the development of the strategic plan as well as the simulation models.

Plan Layout

The plan implementation of the loudspeaker involved various steps which are discussed below. Conveyors were being used each with a varying length of either, 5,10,15 or 20m and then each frame will come at an arbitrary time then put into place by hand in approximately 20 seconds by use of hand through the use of NegExp. The frame is the fed and assembled in each pole plate with a 10% standard deviation and done in approximately 27 seconds. LogNormal takes approximately 29 seconds in order to feed and assemble the magnet with a 10% standard deviation. It took about 26 seconds to build the top plate in a homogenous distribution followed by manual construction of coil and spiders which was done in approximately 45 seconds and then the diaphragm was assembled in about 28 seconds. The dustcover was also assembled manually in 26 seconds and then magnetization took 30 seconds in order to be set up then it took 20 seconds at the automated teller machine.

The final product is shown below.

Design Method

In producing the speakers, there are components of the soft part and the hard part. Hard pieces of an instrument include dust cover, spider, and the diaphragm of the instrument. Conversely, the hard part comprises the pole, magnet, frame as well as the top plate. All of these are located in subassemblies of the engine unit. Integration automation component is the place where the soft components are combined so that they will perform the required integration. The part of the loudspeaker assembly is displayed in the above photo. Lay an end plate on one of the channels and then put a magnet to hold the end plate in its position on the symmetrical line. Place the top plate above the magnet and secure it by the help of the symmetric axis screw to lock the basket properly. Each of the hard elements of the design is equal in measurement. Then, time must be taken to ensure that hard and soft content requirements must be enabled to work harmoniously. Hence, the spider parts embrace the hard parts of the frame and the top plate thereafter. It has a coil resting on a spider and also it can be used as switch. Both the matter of coil and magnet is used for coupling between the cone and frame. Assembly methods are created by software as demonstrated in the following section containing information about Enterprise Dynamics.

The formation of loudspeaker assembly entails a number of complex stages, which requires meticulously synchronized interconnection of shooting equipment, as well as human capital. Assembly atoms are management units of assembly work, which allows each component to be placed in the correct position and incorporated flawlessly. However, the running and management of these operations together with handling of any irregularities and tasks that would call for human intervention is essentially the responsibility of the human resources. It is the Multi-service station that is placed along the assembly line to encourage timely blend of the different levels and styles of assembly: both the automated and the manual. These stations are able to perform a number of services for instance component fitting, quality check as well as adjustments and as such, this had a positive impact on the efficiency of the assembly line.

These two controls are critical in ensuring that the assembly line works for a long time without interruption. These controls entail revisiting the performance of automated systems and the human resources so as to guarantee that the production targets are achieved. The dependability of the system is improved through timely servicing, and most of the problems which may occur during the assembling of the SETs are addressed scientifically and instantly. Availability and reliability control is vigorous in that successful implementation of these measures will ensure that the production line is on for most of the time and will therefore attain the production rate of one loudspeaker per thirty seconds.

Simulation and optimisation of the whole assembly process is carried out by the Enterprise Dynamics (ED) software. It is possible to build complex models where statistical aspects are included as part of a 3D object and thus conduct formal examinations and verifications of the connection strategies. The simulation results then are a powerful tool for predicting the sources of delay and poor flow of materials and work, thus aiding the design team in determining change. After devising as well as implementing the experiments, there exists a careful approach in the simulation analysis and interpretation of the results with the aim of noting areas of improvement and to guarantee that the assembly process is run as effectively as possible. The holistic framework outlined in this assignment therefore highlights the need to apply the concepts of design and simulation in order to design a superior, high-performance manufacturing system.

ED model

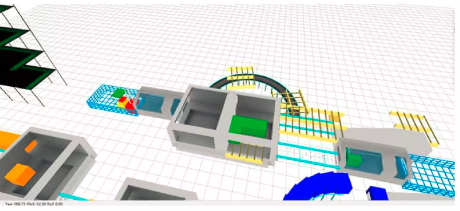

When the team was making a model in the Enterprise Dynamics programme, they worked very hard to include all the details of how loudspeakers are put together. With the flexible features of Enterprise Dynamics, they added 3D objects, such as workstations and conveyors, to correctly show how the facility is laid out. Statistical values from the first investigation, data gathering, and analysis were carefully used to create scenarios that were as real as possible.

Figure 4: Model design for factory

(Source: Retrieved from Enterprise Dynamics)

The model’s functionality was thoroughly tried and confirmed, making sure that it accurately showed how automated and manual assembly processes work together. Using Enterprise Dynamics, the team was able to capture how dynamic the production system was, which let them look at different situations and find the best settings for key parameters. This advanced modelling tool made it possible to fully assess the system’s performance, giving very useful information for later steps in the process of optimising loudspeaker production.

Result

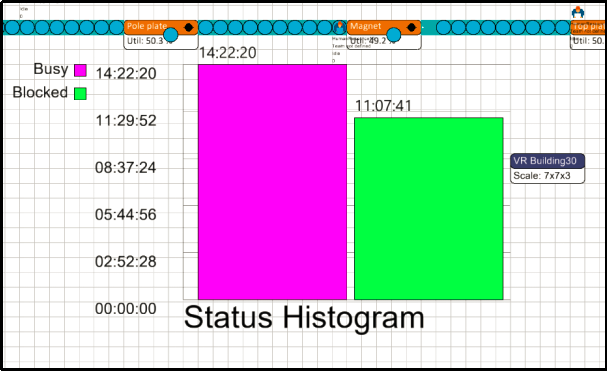

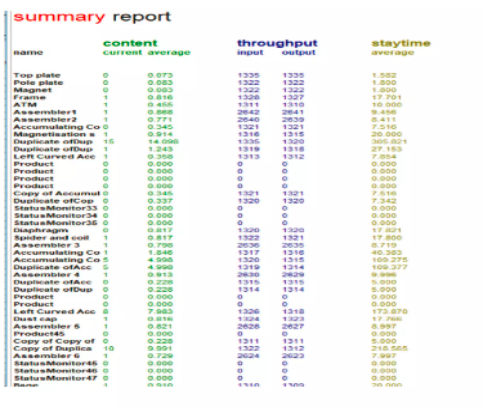

The entire overview of the loudspeaker assembly process is provided by the simulation results from Enterprise Dynamics, which shed light on numerous operational factors. The throughput values show how efficient the production line is; for example, the “Pole plate,” “Magnet,” and “Top plate” stages all achieve throughput percentages above 99% on average. This points to an efficient system-wide movement of components across these stages.

Figure 5: Simulation Status Plot

(Source: Retrieved from Enterprise Dynamics)

Figure 6: Summary Report

(Source: Retrieved from Enterprise Dynamics)

However, it is necessary to admit that certain domains reveal quite significant challenges which can be illustrated with references to the “Accumulating Co” and similar projects. Meantime, the values reflecting the fact that some of the parts components’ stay time indicate that they are processed for a longer time, creating problems of bottlenecks. The accumulation phases, namely Copy of Accumulating Co and Copy of Copy of Accumulating Co, show much higher stay times than other phases, suggesting that the portions of the assembly process depicted by these names need improvement.

Furthermore, the rates of consumption of several resources including ‘Robot17’ and human resources are not the same; there are occasions where some of these resources are hardly utilized. This indicate that there is room for increasing total organisational throughput by better coordinating and balancing the use of resources so as to decrease the times when the apparatus is inactive and increase working speed.

In some regions, for example, the simulation shows high work capacity regarding the type and productivity of tasks, but problems with the duration of the collection and the irrational distribution of resources remain unresolved. Due to the appraised aim of producing one loudspeaker in 30 seconds, it is essential to manage time and the pile up processes effectively. It can be done either by adopting the use of parallel processing or reallocation of some of the resources to allow for the achievement of better efficiency in the production line.

The analysis of the simulation results implies that there is a constant need for improving planning and designing of processes and layout. In this respect, with the help of Enterprise Dynamics the presented research pointed out the directions of its improvement, as well as gave the practical recommendations for amplification of the subsequent loudspeaker assembly. From these conclusions, it is clear that adjustments should be made continually to enhance the functionality of the manufacturing system in its bid to construct a stronger and more effective production line of loudspeakers.

Discussion & Conclusion

Discussions

Based on the literature review, both primary and secondary data collected, a comprehensive research was conducted on audio conferencing systems using group flow simulation tool enterprise dynamics for process planning and document analysis along with facility layout design. It proved useful to elaborate this study and to fine-tune the findings made. The synthesis of the research in this area categorized current problems on acoustic material and its manufacturing techniques. Lastly, it presented approaches for the production of the material. Below is the plan for how to implement methods to introduce both the manual and automated techniques in the conference.

The flow chart used to show facility layout depicted a series of activities involved in assembling the products, arrangements that incorporated the use of automated systems together with employees. Further detailing of this innovative layout was done and translated into a simulation model, with Enterprise Dynamics. Through the simulation results, the outlines of the manufacturing system to be developed were given and high throughput rates at some of the stages and congestion and related inefficiencies concerning accumulation and resource management were depicted.

In this aspect, the simulation exposed a number of challenges, with emphasis on the long time that products spend before accumulating at specific steps. Solving these problems entails modifying the model’s performance or working on the parameters that had been used. This may mean rethinking the design of the process of accumulation, the introduction of parallel processing, or the redistribution of resources. The difference in activities and resource means that there can be further enhancements to its tasks that can be either automated or still manual. The study also learnt the advantages of manual intervention as well as integration with automation systems of Operations Management using Enterprise Dynamics to search out more of the opportunities for enhancement. The conclusions, thus, also underline the importance of the regular improvement in planning as well as configuration of layouts for processes and facilities to further maintain the performance at an optimal state in the evolution of audio conferencing technology and production.

Conclusion

The assignment integrates theoretical insights with practical modelling and simulation to approach loudspeaker construction holistically. Modern manufacturing is complicated, thus the assignment is interdisciplinary from materials science to production system optimisation. Enterprise Dynamics modelling provides a path for improving the assembly process to produce one loudspeaker every 30 seconds.

The assignment emphasises how crucial it is for system and product designers to work together to create a harmonic and effective production system, and it also shows how important simulation is to optimising such complex processes. The iterative process used in this work paves the way for ongoing innovation and development in the ever-changing loudspeaker manufacturing industry.

References

Zenker, B., Dannemann, M., Geller, S., Holeczek, K., Weissenborn, O., Altinsoy, M.E. and Modler, N., 2020. Structure-integrated loudspeaker using fiber-reinforced plastics and piezoelectric transducers—Design, manufacturing and validation. Applied Sciences, 10(10), p.3438.

Bevrnja, M., Imamović, Z. and Bisić, M., 2022. ADDITIVE MANUFACTURING APPLICATION FOR THE INCLUSION OF THE VISION IMPAIRED POPULATION IN PUBLIC TRANSPORT. Annals of DAAAM & Proceedings, 33.

Downey, K., 2021. Loudspeaker array and testing facilities for performing large volume active noise cancelling measurements.

Yang, D., Zhang, L., Wang, L. and Wang, K., 2023. Recent Advances in Flexible Nanogenerators for Microphone and Loudspeaker Applications. ACS Applied Electronic Materials, 5(11), pp.6063-6078.

Lawrence, A.J., Allison, J. and Naify, C., 2022, December. A modular multi-material printed acoustic loudspeaker. In Proceedings of Meetings on Acoustics (Vol. 50, No. 1). AIP Publishing.